This is just a placeholder headline, we will replace it.

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet.

Fluid System Efficiency and Transient Heat Transfer Analysis

Unmanaged heat or inefficient flow is a severe operational risk. I provide specialized CFD consulting to accurately map fluid dynamics, pressure drops, and transient heat transfer (S_R8) within your systems. This analysis guarantees optimal thermal performance and fluid system efficiency, eliminating the need for costly physical redesigns.

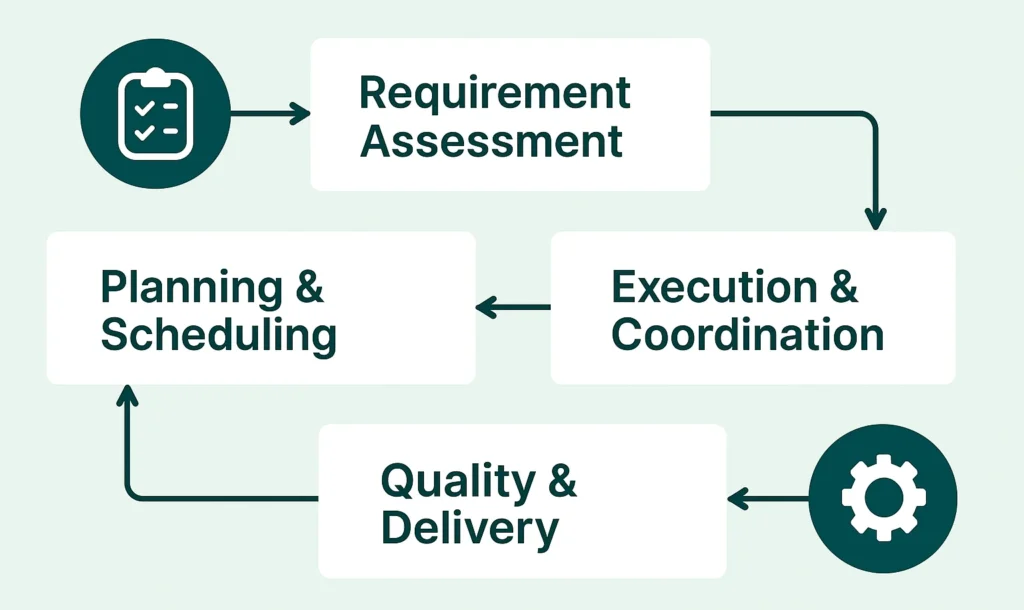

Fluid Dynamics Workflow: The 6-Phase Predictive Modeling System

High-stakes fluid or thermal projects demand scientific rigor. This comprehensive methodology ensures every CFD analysis is set up, solved, and verified against physical laws, translating complex flow visualization into guaranteed system efficiency and optimal thermal performance.

CAD Geometry Optimization

Preparing the CAD geometry by simplifying internal topology and removing irrelevant details to ensure stable and efficient volume meshing for the flow domain.

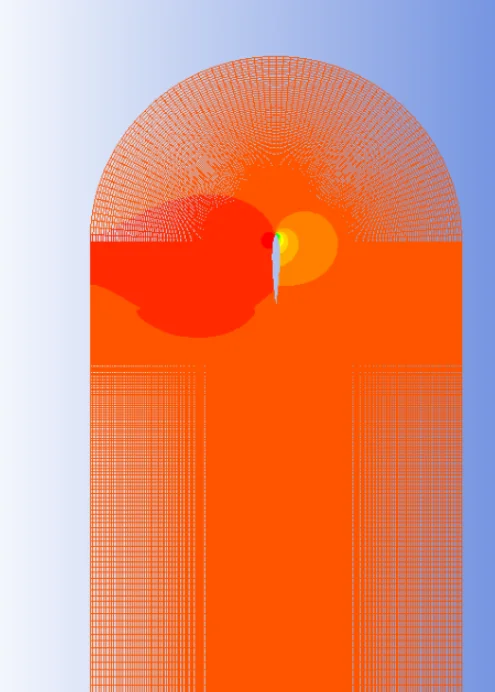

Volume Meshing & Grid Quality

Creating the optimal control volume grid to balance solution accuracy against computational resources, which is critical for capturing flow boundary layers accurately.

Boundary Conditions Setup

Precisely establishing inlet/outlet mass flow rates, turbulence models, fluid properties, and wall conditions (S_R4, S_R5) for accurate real-world simulation replication.

Solver Execution & Stability

Running steady-state or transient heat transfer analysis (S_R5) across thermal and fluid domains to generate high-resolution velocity and pressure data (S_R8).

Post-Processing & Flow Insight

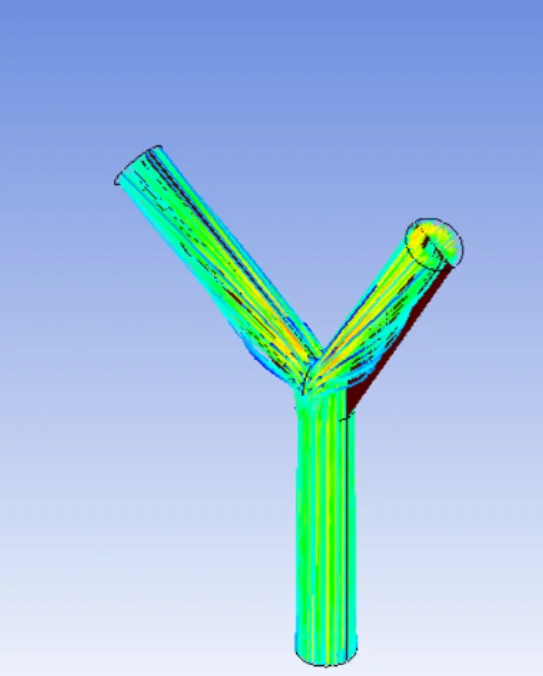

Extracting data visualization (flow vectors, pressure maps, heat flux) and identifying areas of high pressure drop, turbulence, or inefficient heat transfer (S_R4).

Recommendation & Optimization

Converting complex simulation data into clear, actionable design adjustments (e.g., baffle placement, duct resizing) to achieve guaranteed fluid system efficiency.

Predictive Certainty: The Measurable Advantages of Predictive Engineering

Unmanaged heat or inefficient flow creates severe operational risks. This service provides the predictive intelligence required to maximize system lifespan, ensure compliance, and confidently guarantee thermal and fluid performance. These benefits show how data-backed analysis becomes your competitive advantage.

Energy Optimization and Flow Efficiency

We map flow velocity and pressure drops within complex fluid systems (like internal piping or valves), directly identifying and removing bottlenecks to optimize energy use and output.

Thermal Stability Assurance

We master heat management by accurately analyzing transient heat transfer (S_R5, S_R8), preventing component overheating and guaranteeing the system operates reliably within safe thermal limits.

Clarity, Not Complexity

We translate complex flow visualization and data into clear, concise, and actionable design recommendations that your team can implement instantly, not just raw analytical output.

Predictive Performance Guarantee

By testing virtually, we provide data certainty on flow stability, pressure loss, and cooling capacity, eliminating guesswork and ensuring reliable operation under load.

Faster Design Decisions

Virtual testing allows you to evaluate dozens of configurations (e.g., baffle positions, duct geometry) instantly, drastically reducing the design loop and accelerating your time-to-market.

Direct Expert Partnership

You partner directly with a dedicated engineer who ensures the CFD analysis is perfectly aligned with your commercial goals, providing personalized support and singular accountability.

Have a Design, Simulation, or CAM Requirement?

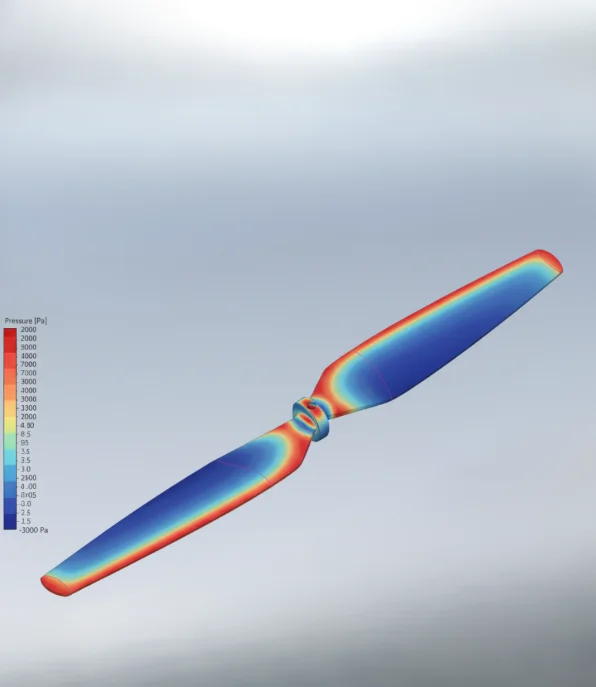

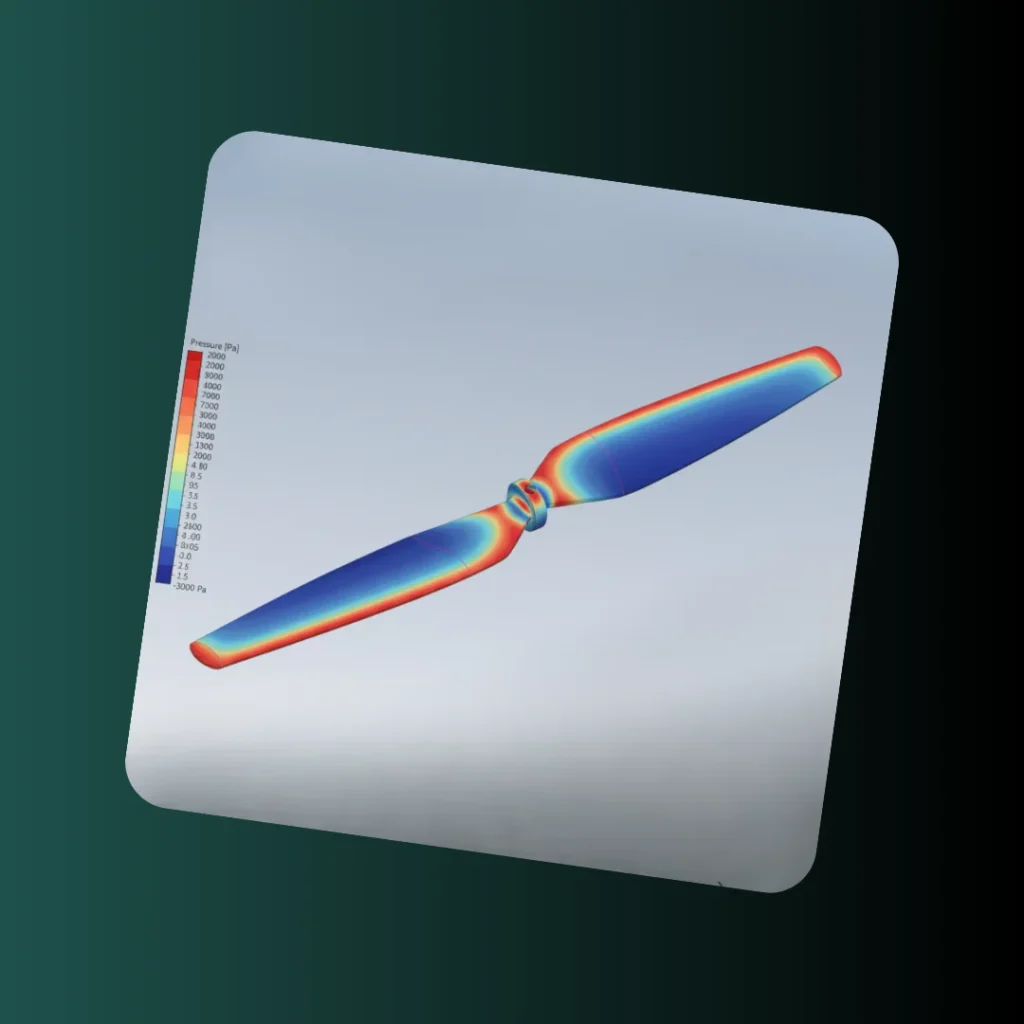

Aerodynamic Optimization: Enhancing Drone Propeller Thrust and Efficiency

The objective was to optimize a drone propeller blade design using advanced CFD analysis to maximize thrust and efficiency under various flight conditions. This project utilized ANSYS Fluent to model …

Efficiency GoalMaximize Thrust/TorqueAnalysis SoftwareANSYS Fluent CFDFlow ModelingComplex Airflow SolvedOptimization FocusAerodynamic Efficiency

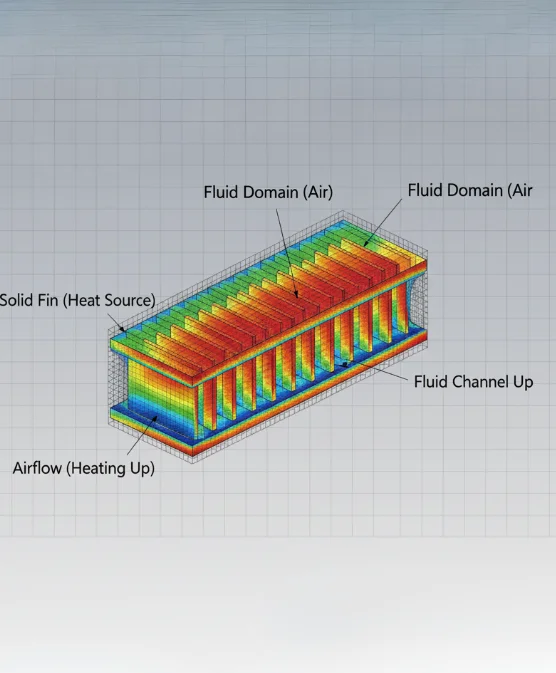

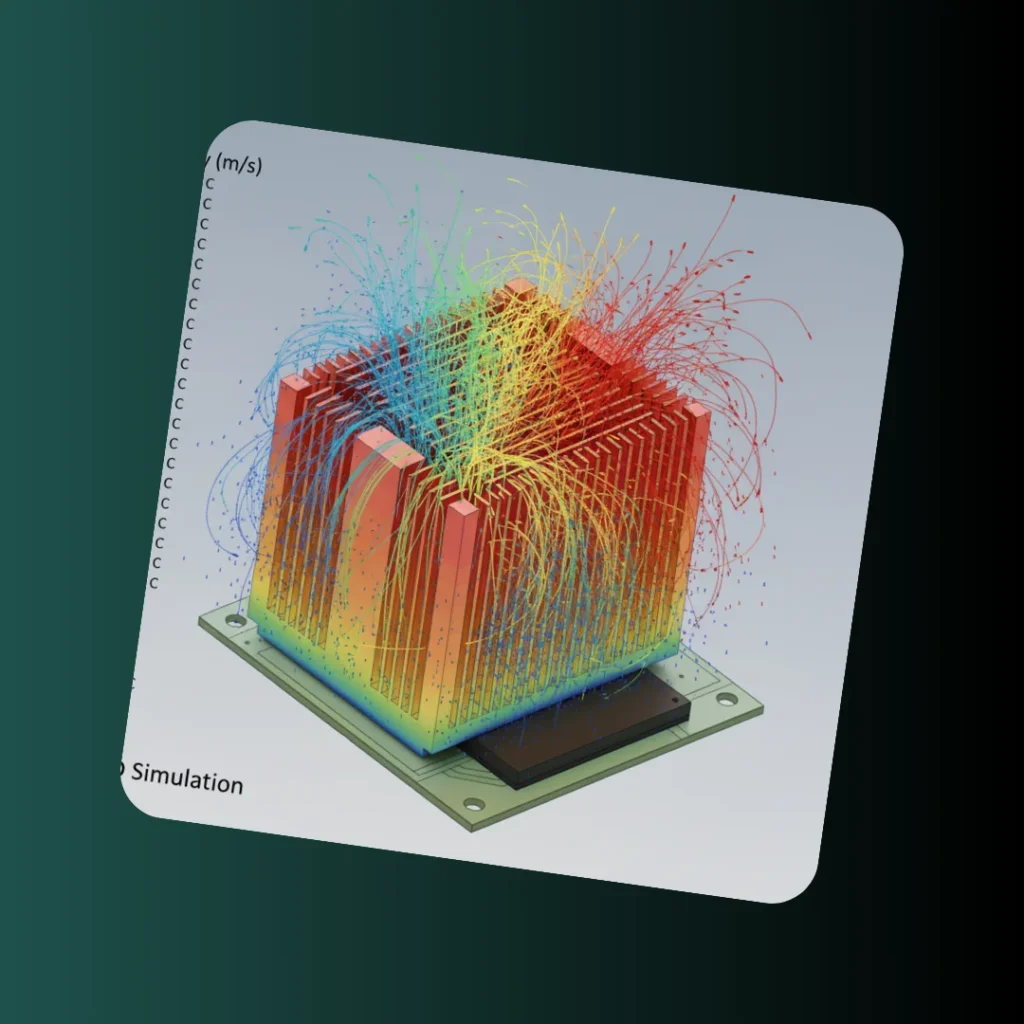

Thermal Management: Optimizing Heat Sink Design for Electronics Reliability

The objective was to design and validate an optimized heat sink to ensure a critical electronic component (e.g., CPU, power transistor) operates within safe thermal limits. This project utilized ANSYS …

Analysis SoftwareANSYS Steady ThermalThermal ComplianceVerified Max TemperatureCooling PerformanceHeat Dissipation OptimizedFin GeometryDesign Iterations Checked

Let’s Clear Things Up

What is the main difference between CFD Analysis and Structural FEA?

CFD (Computational Fluid Dynamics) focuses entirely on fluid behavior, heat transfer, and airflow. Structural FEA (Finite Element Analysis) handles stress, vibration, and component integrity. They solve fundamentally different physical problems.

Can CFD help solve overheating problems in electronics or complex enclosures?

Yes. I specialize in thermal management consulting (S_R6, S_R8). CFD accurately models airflow and transient heat transfer (S_R6) within enclosures and PCBs, allowing us to find hotspots and optimize cooling systems virtually.

How do you analyze and fix inefficiency in complex pipe or duct networks?

We use CFD simulation to accurately map pressure drops, flow velocity, and turbulence (S_R5). This pinpoints bottlenecks and allows for optimized geometry (like baffle placement or pipe resizing) to improve overall fluid system efficiency.

What is transient analysis, and when is it necessary for a fluid project?

Transient analysis (S_R6) is essential when flow or heat changes over time (e.g., pump start-up, thermal cycling). It predicts time-dependent behavior, giving you certainty on dynamic performance that steady-state analysis misses.

How reliable are the CFD flow predictions compared to real-world performance testing?

When boundary conditions are set correctly, CFD simulation results are highly reliable. I ensure the virtual environment accurately models real-world fluid dynamics and material properties, guaranteeing actionable data.

Do you handle external projects like aerodynamics or wind load calculations on structures?

Yes, CFD analysis covers external flow, including optimizing aerodynamics for vehicle components or calculating wind loads on structures (S_R6). The same principles apply to mapping airflow and pressure.

How will my non-technical team be able to understand the complex flow visualizations?

I translate complex data into clear, concise, and actionable recommendations. The final reports feature intuitive pressure maps, flow vectors, and temperature plots that simplify the technical insights for all stakeholders.

How does investing in CFD save me money compared to physical fluid testing?

CFD consulting eliminates the massive cost and time involved in physical flow testing. We test dozens of virtual iterations instantly, drastically reducing development costs and accelerating your time-to-market.

Can simulation diagnose why my existing pump or valve system is performing poorly?

Absolutely. We use reverse analysis to pinpoint the exact pressure drop or turbulence issue responsible for the underperformance. CFD analysis is the most effective tool for troubleshooting existing fluid system inefficiencies (S_R5).

Which advanced software platforms do you use for high-level fluid dynamics?

I work with industry-leading platforms such as ANSYS Fluent (S_R6, S_R9) and specialized CFD solvers. This ensures your analysis is based on verified, robust, and industry-standard solver technology.