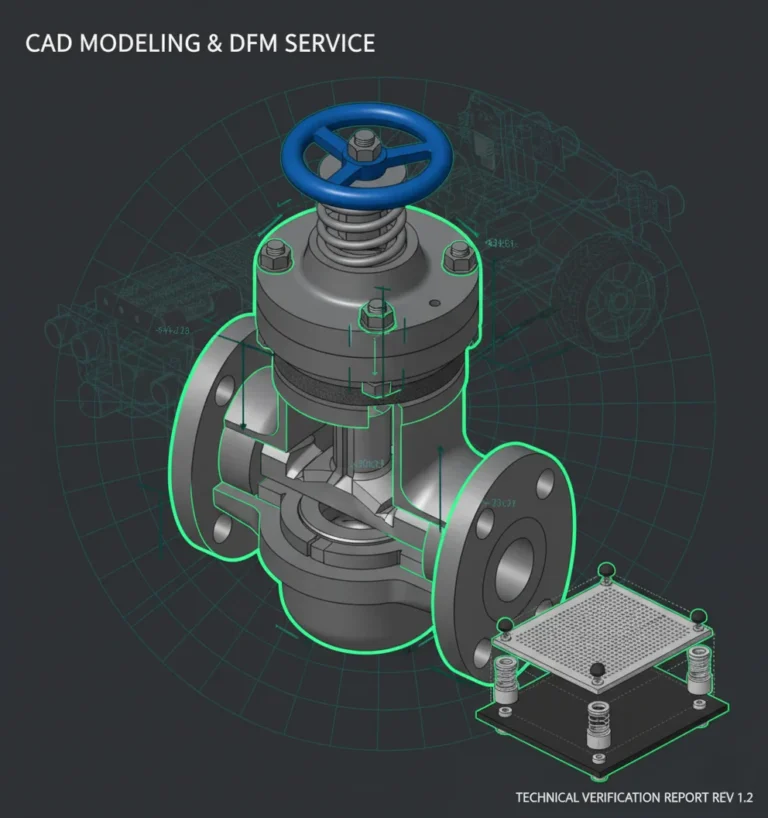

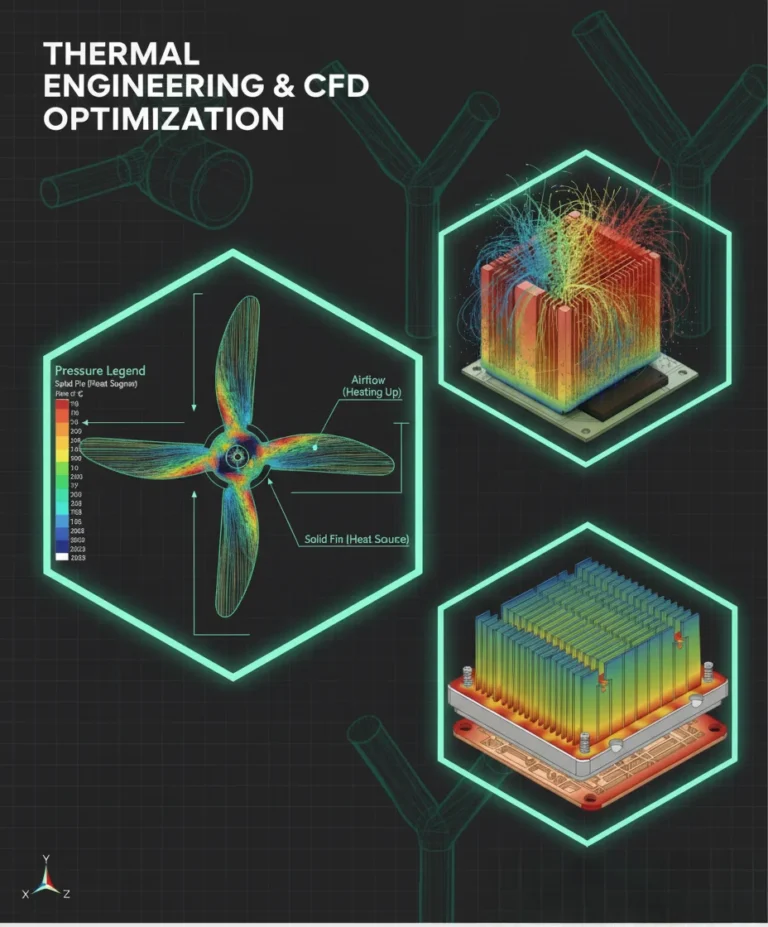

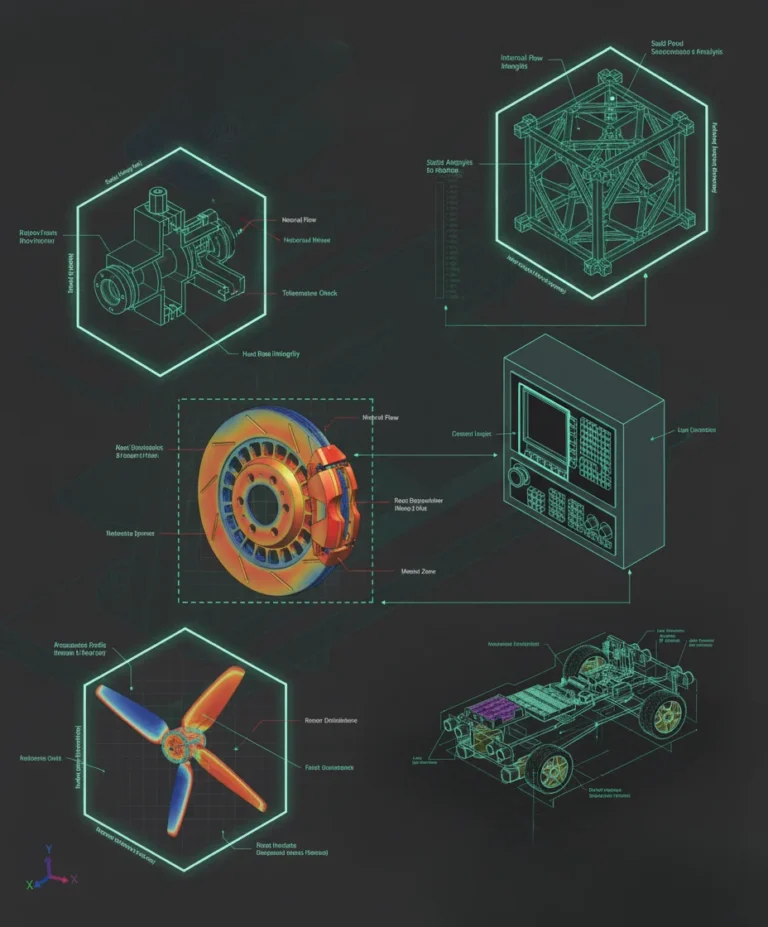

Turnkey Mechanical Simulation: Structural FEA, CFD & Product Design Validation

Predictive engineering demands guaranteed solutions. This specialized mechanical engineering simulation service is delivered under a clear Statement of Work (SOW). The structured process ensures predictive budgeting and integrates structural FEA, CFD optimization, and DFM engineering. All projects conclude with verified design validation reports, guaranteeing maximum reliability assurance.

Behind Every Design, There’s a Story

I started as a curious student fascinated by how machines think, move, and work. That curiosity turned into a passion for building solutions that merge art with engineering. Over the years, I’ve explored CAD design, simulation, research, and automation, not just to design systems, but to make them smarter, simpler, and stronger.

-

Experience Across CAD, DFM, FEA & CFD Systems

-

Constant Learner with a Research Mindset

-

Collaboration-Driven Work Philosophy

Mechanical Design, Simulation & Optimization

What Makes My Process Stand Out Among Others

Other Firms

Team Rotation

Multiple engineers handle your project at different stages.Fixed Procedures

Predefined workflows with little customization.Formal Channels

Slow response and limited client interaction.High Costs

Extra charges for admin and management.Multiple Hands

Different people, different priorities.

With Me

Personal Attention

Each project receives focused input and detailed care.Adaptive Strategy

Designs evolve based on your feedback.Open Communication

Direct updates and honest timelines.Cost Efficiency

You invest in value, not overhead.Consistency & Trust

One person, one vision, from start to finish.

Trusted by Clients Around the World

Strong partnerships are built on results and reliability. Over the years, I’ve worked with clients across industries, helping them bring ideas to life through efficient design and simulation. Their words reflect the quality and commitment that define every project I take on.

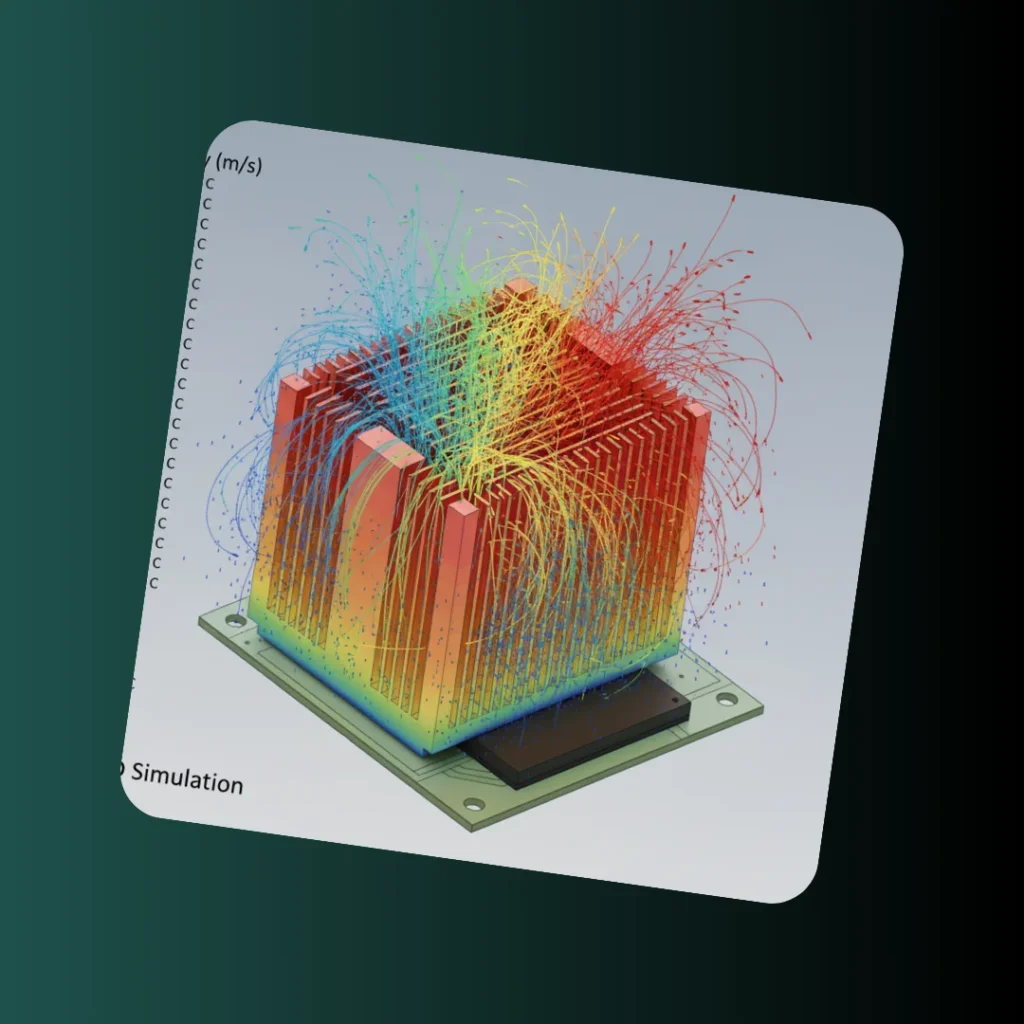

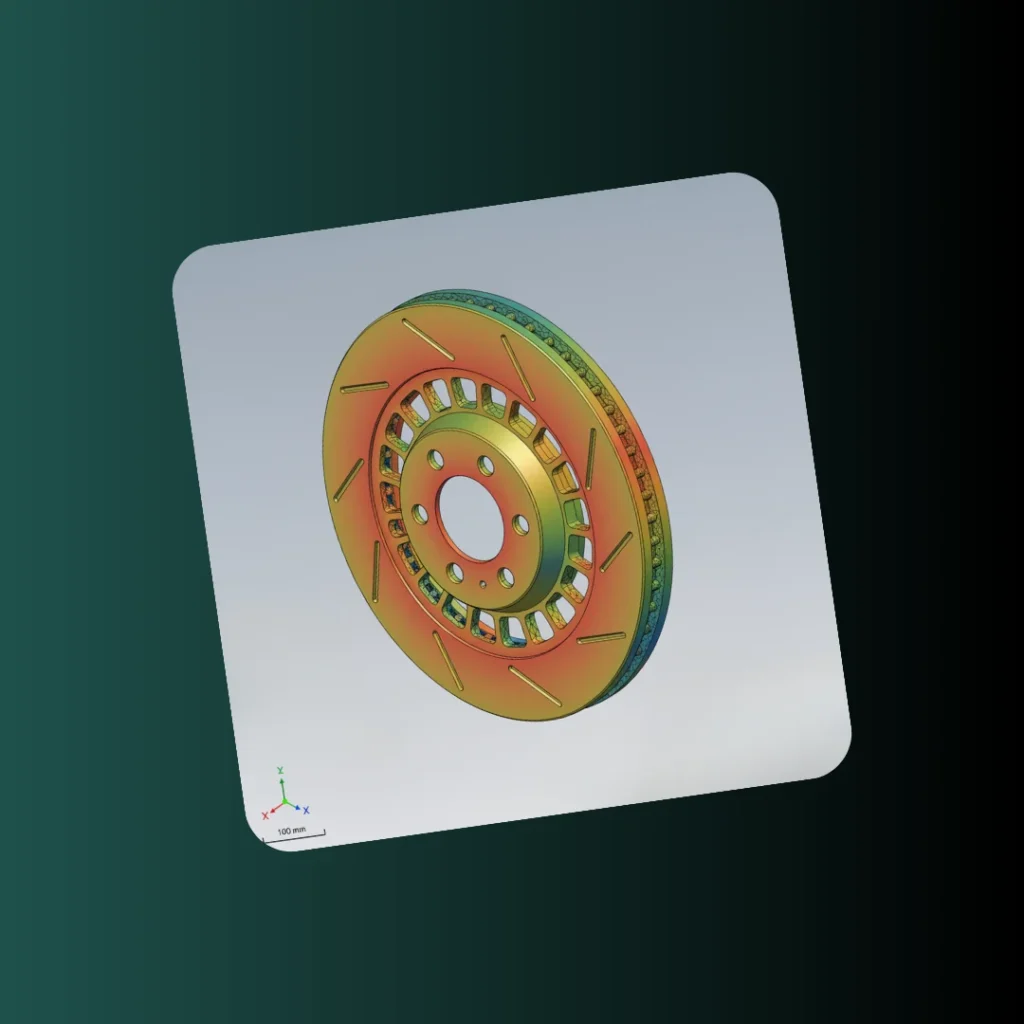

Our primary concern was thermal compliance under heavy load. His methodical CFD thermal analysis pinpointed exactly where our original design failed and provided the optimized geometry. We got the definitive assurance needed to move into manufacturing, drastically mitigating long-term failure risk. It was a highly professional, data-driven solution.

Yumi Takahashi

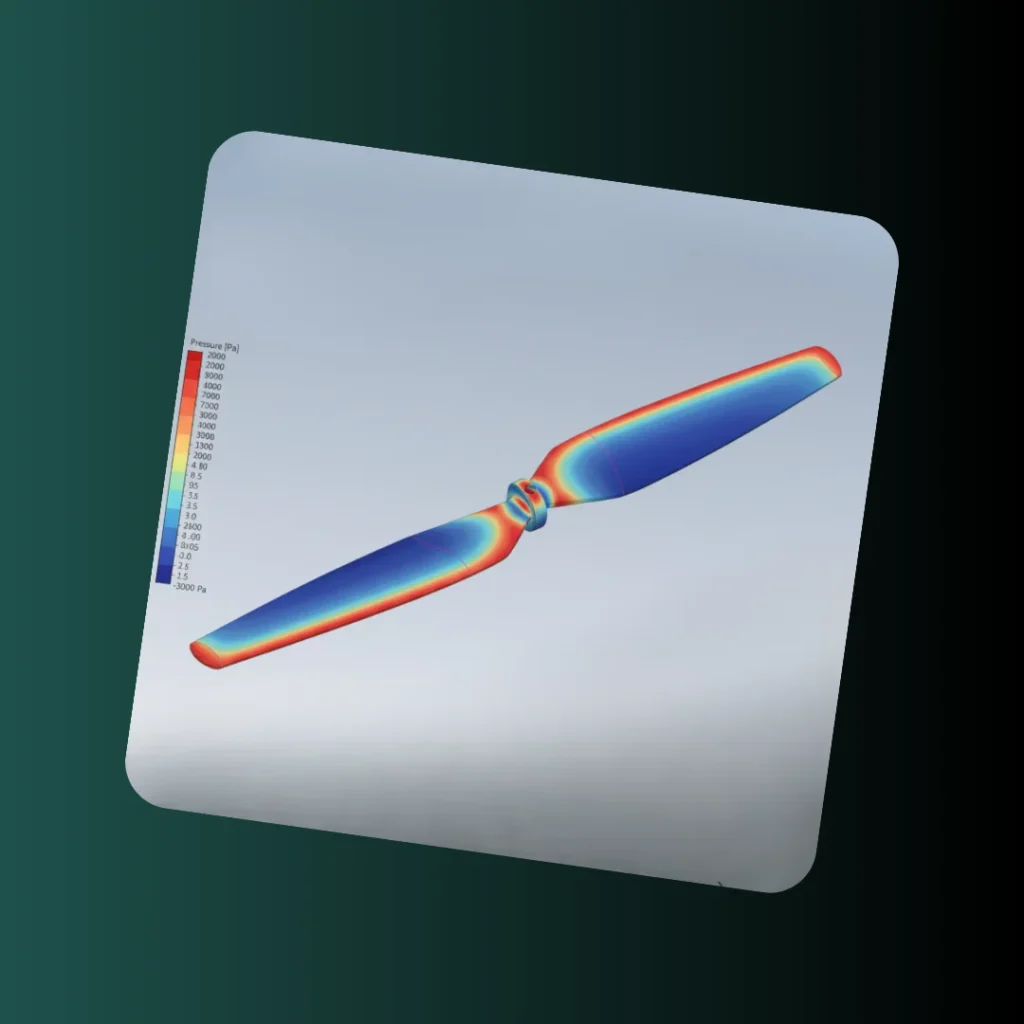

Product Assurance ManagerIn the drone market, efficiency is everything. We needed data that was absolutely trustworthy. Touseef’s CFD analysis was strategic, he didn’t just model, he provided verifiable efficiency metrics that justified our design changes. It was a precise, high-level partnership that saved us months of physical testing.

Ama Boateng

Director of Product DevelopmentFor safety-critical components, we need assurance, not just data. The challenge here was working only from old design drawings. The engineer’s expertise in 2D-to-3D analytical reconstruction was flawless, transforming our legacy data into a fully verified digital asset. This process gave us the definitive safety factor required for structural sign-off. Highly recommended expert.

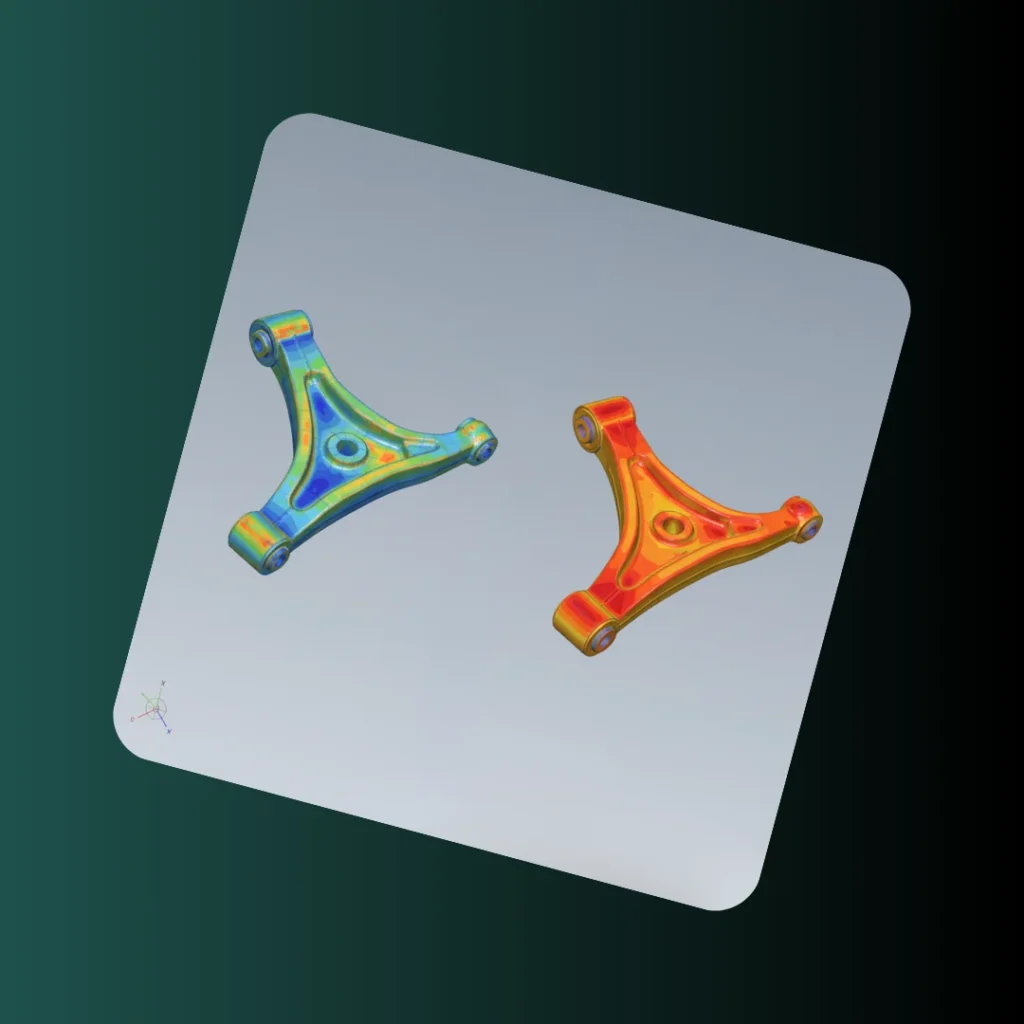

Hana Fujimoto

Automotive R&D DirectorI needed hard data to back up my design thesis. Touseef delivered more than just a simulation; I received a full structural analysis report checking displacement and FOS. The process was fast, and the ANSYS data was crystal clear. It allowed me to validate my theoretical model perfectly.

Kwame Mensah

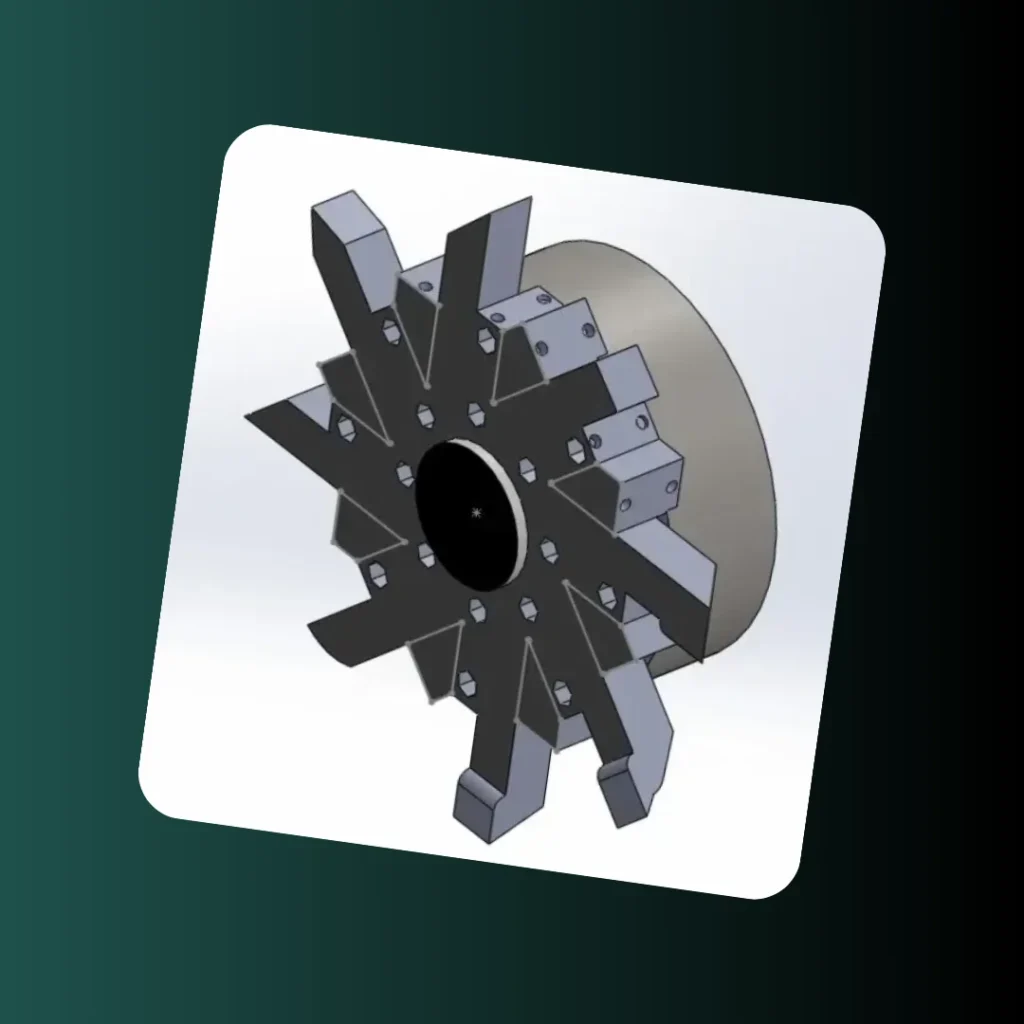

Automotive Engineering StudentWorking on a mission-critical part like a tool turret requires more than just modeling, it needs verified indexing accuracy. The engineer’s detailed rotational mating verification saved us from potential indexing failures on the machine. The geometry delivered was robust and completely CAM-ready.

Darren Hayes

CNC Systems EngineerThe objective was visualization and documentation purity. The final 3D CAD model was geometrically flawless, and the clean parametric history made it incredibly easy for our team to integrate into our technical archives. It was exactly the high-fidelity asset we needed for our internal presentations.

Hassan Al-Masri

Engineering Student

Tell the World How We Did

If we’ve worked together, I’d love to hear your experience. Your words not only help me grow but also guide others in choosing a partner who values precision, clarity, and collaboration.

Here’s What I’ve Been Working On

Let’s Clear Things Up

What kind of projects do you work on?

I handle mechanical design, simulation, and optimization projects, including CAD modeling, FEA/CFD analysis, and research-driven engineering work.

Do you work with international clients?

Yes, I collaborate with clients and teams across the world remotely through structured communication and flexible time coordination.

Which software do you use?

I mainly work with SolidWorks, Ansys, and Autodesk, along with other analysis and automation tools depending on project needs.

Can you handle both small and large-scale projects?

Absolutely. I work with individuals, startups, and research teams , adjusting my workflow and scope according to the project size.

How do you ensure quality in your designs?

Every project goes through a detailed process involving design validation, simulation, and review to ensure accuracy, durability, and performance.

Do you provide project reports or documentation?

Yes, all deliverables come with complete documentation, including design files, reports, and visual presentations if required.

How does your process work?

It starts with understanding your goals, followed by concept design, development, simulation, and feedback rounds before final delivery.

What’s the usual turnaround time for a project?

It depends on the scope, but most projects are completed within a few days to a couple of weeks, keeping quality and communication consistent.

Can I request changes during the project?

Of course. I maintain open communication throughout the project to make sure your input is considered at every step.