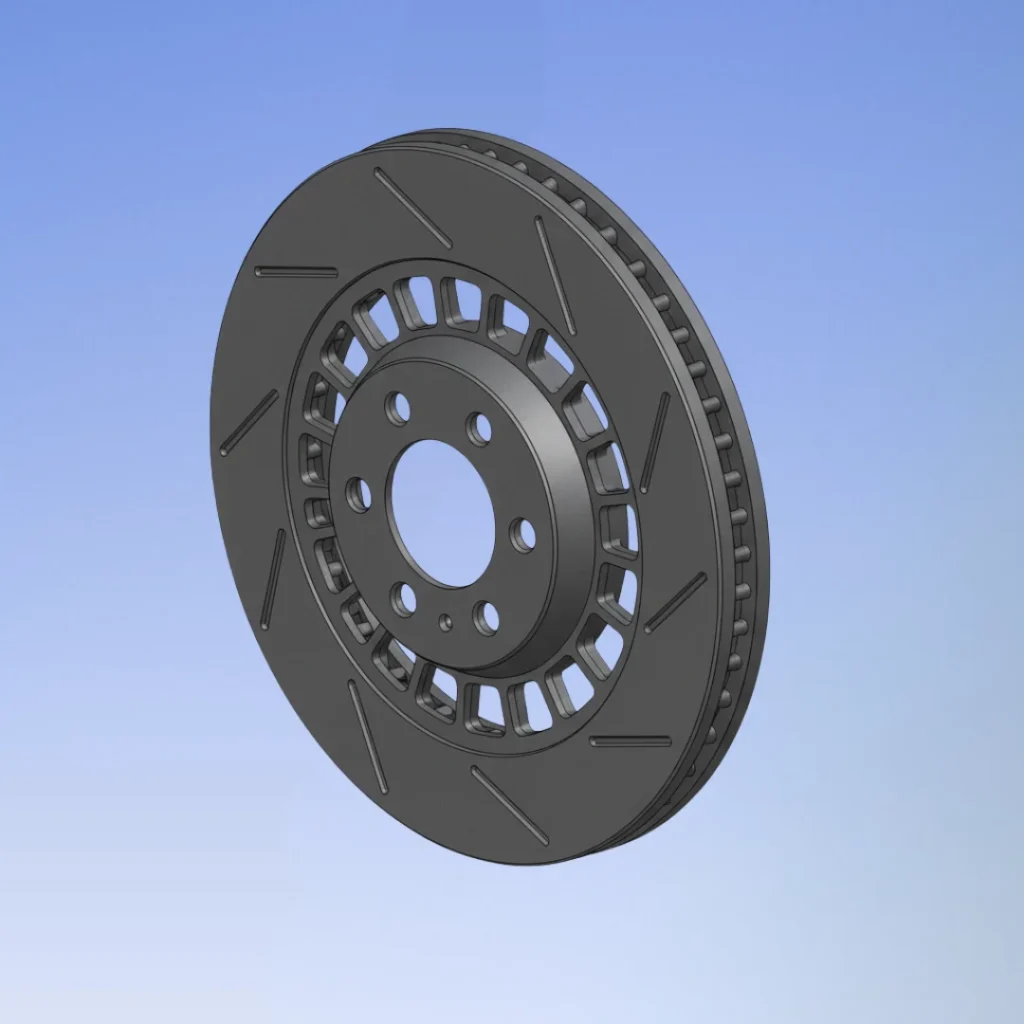

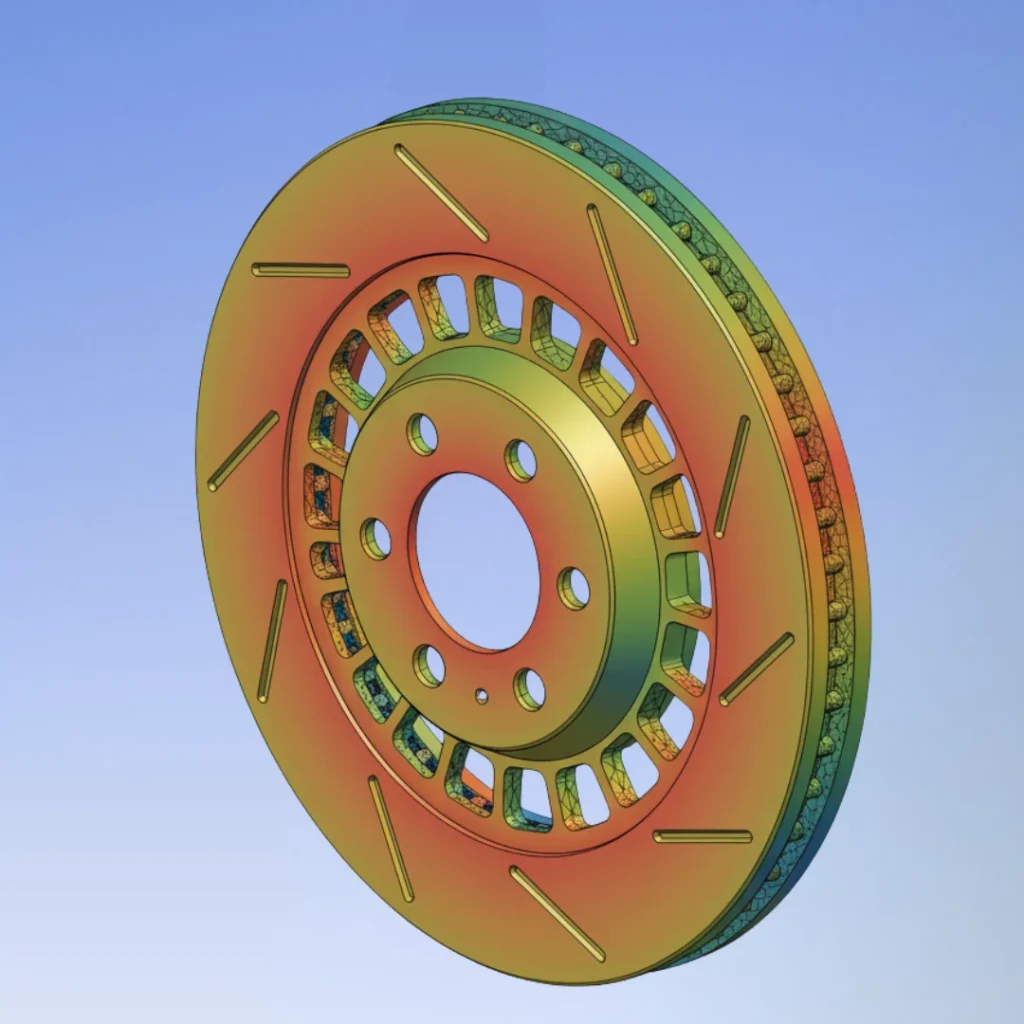

Static Structural Analysis: Verifying Automotive Brake Rotor Reliability

The client needed to model their theoretical brake rotor design and verify its performance under maximum load conditions. This project utilized SolidWorks CAD modeling and ANSYS Static Structural analysis to check critical stress, strain, and Factor of Safety (FOS) metrics, providing a definitive validation report for the design’s structural reliability.

How This Project Took Shape Step by Step

CAD Modeling & Import

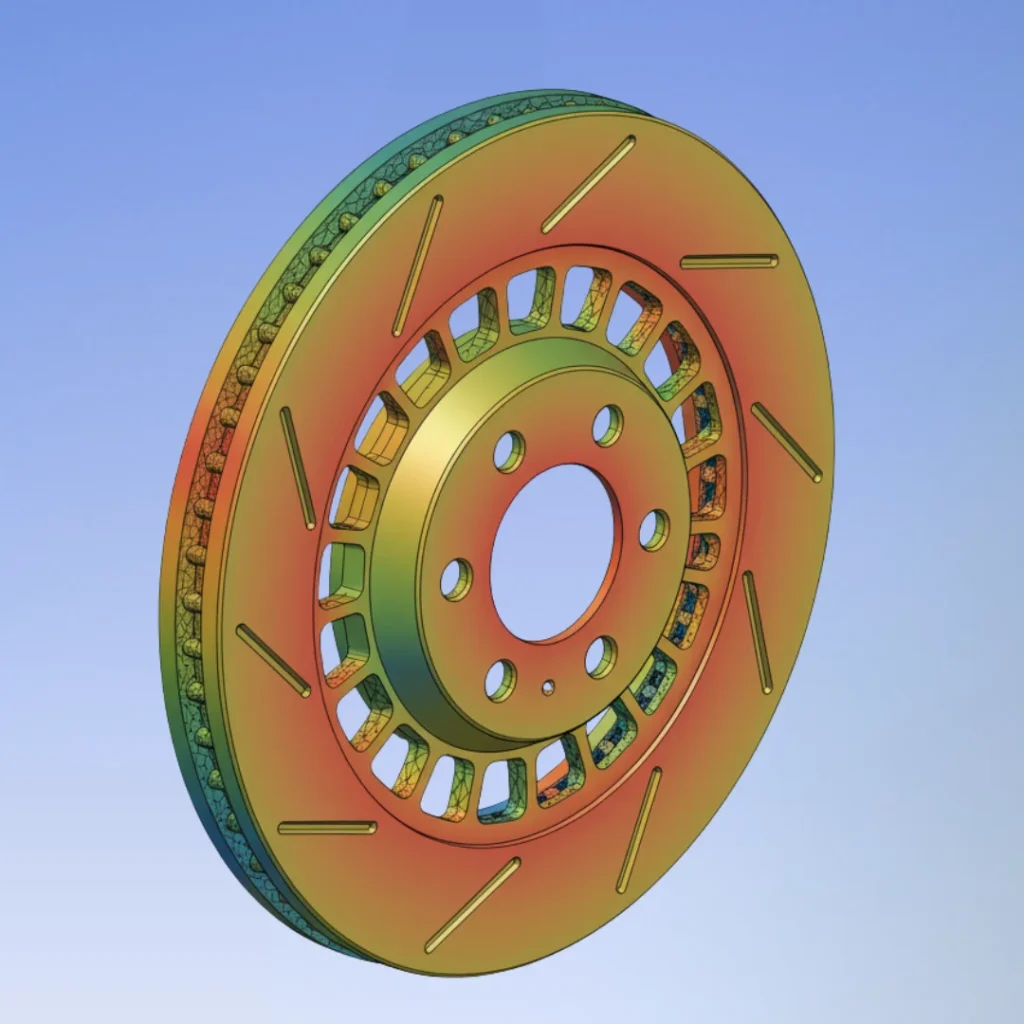

Created the high-fidelity brake rotor CAD geometry in SolidWorks, ensuring precise slots and ventilation structures. The model was then imported cleanly into ANSYS Mechanical, performing necessary geometry cleanup to prepare the component for high-fidelity finite element meshing.

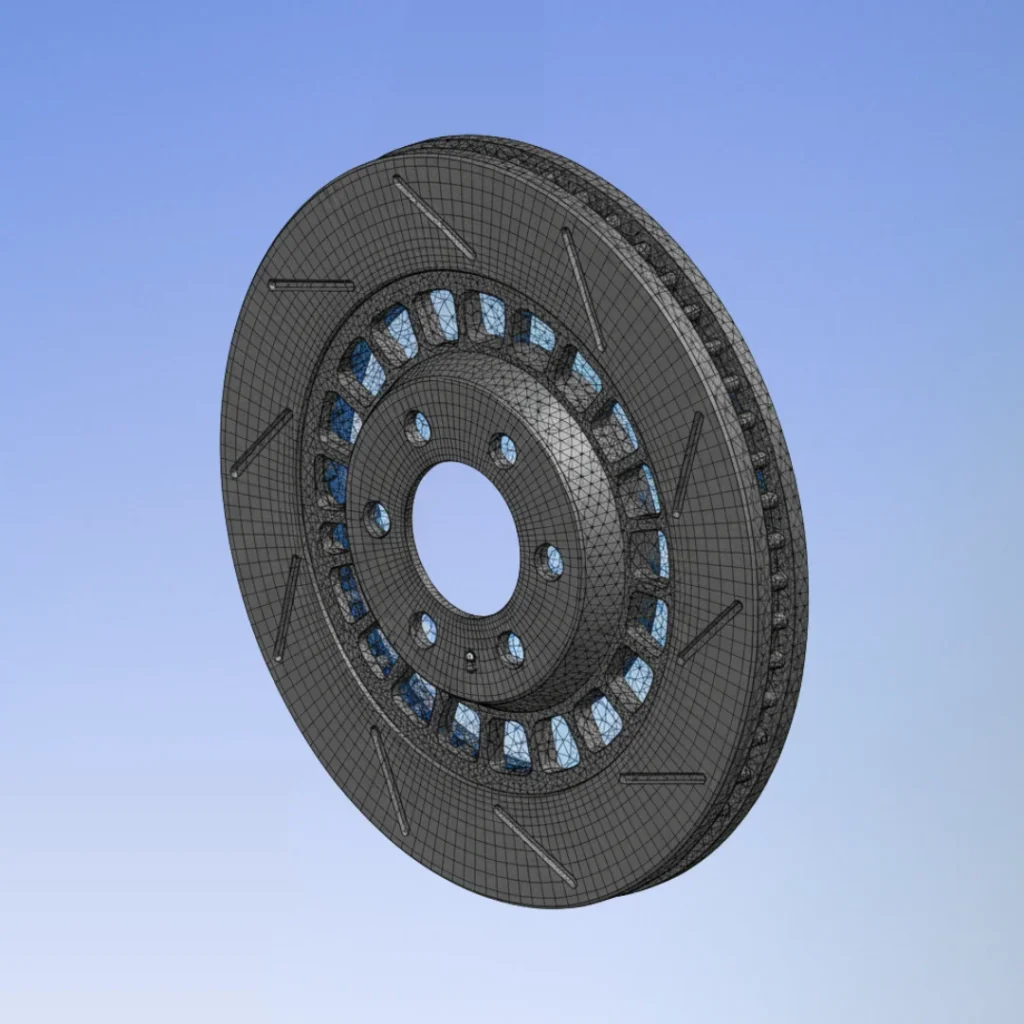

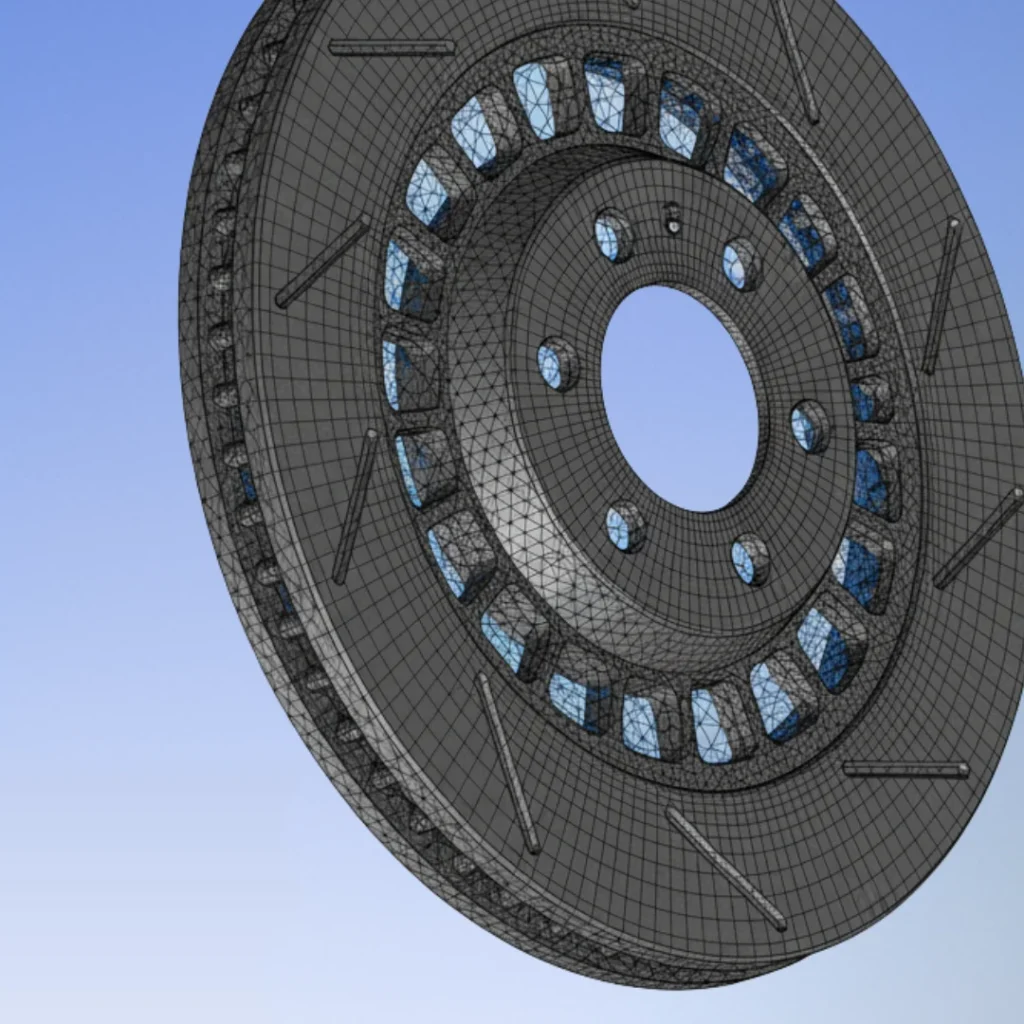

Meshing & Element Optimization

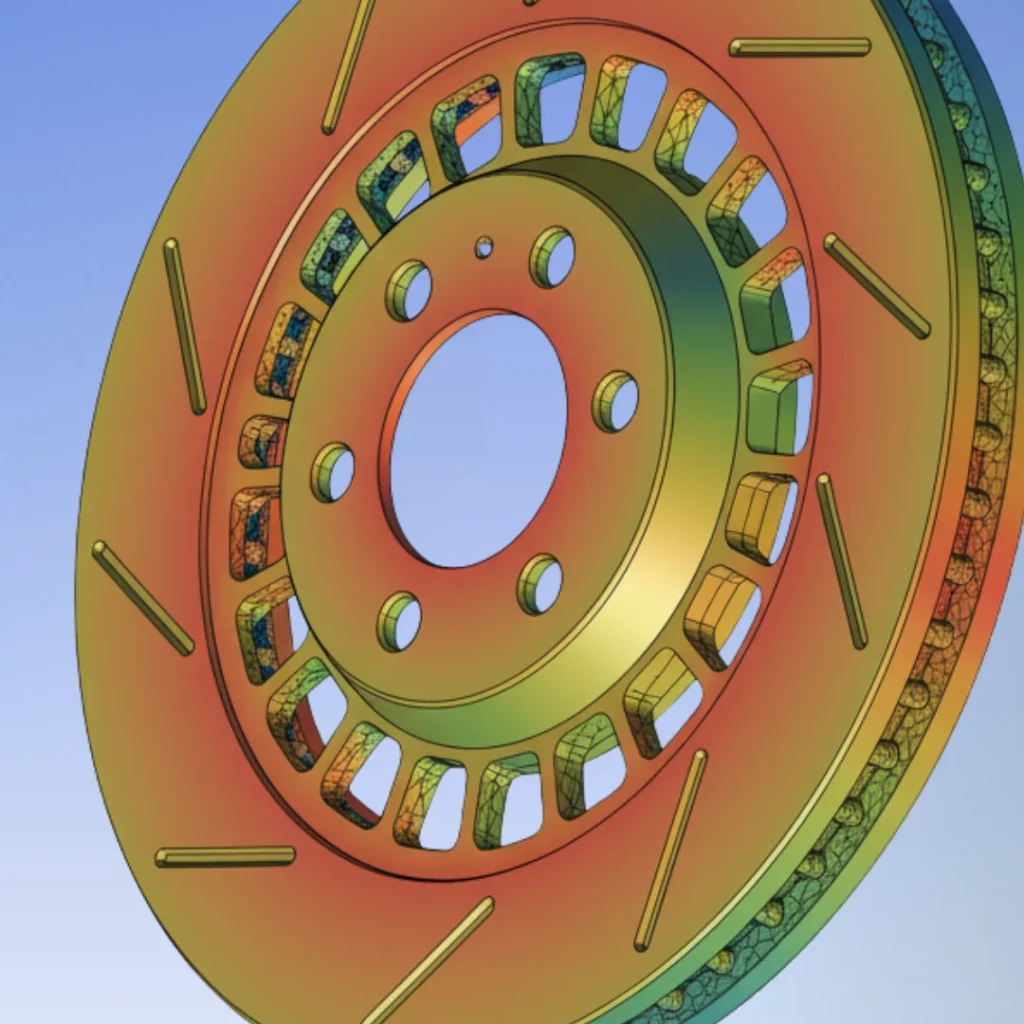

Generated a refined finite element mesh, optimizing element size and density specifically in the critical high-stress areas (e.g., ventilation holes) to ensure the accuracy of the static structural analysis results without unnecessary computational overhead (S_R3).

Boundary Conditions Setup

Applied realistic operational constraints, including fixed supports at the hub connection points and the specified maximum braking torque/pressure loads to simulate the worst-case scenario. This accurately established the virtual testing environment for structural stress analysis (S_R4).

Solver Execution & Validation

Executed the ANSYS Static Structural solver to determine the resultant Von Mises stress, strain, and displacement across the entire rotor body. This phase confirmed the structural response matched theoretical predictions under the extreme braking load.

Post-Processing & Safety Factor

Extracted and post-processed the critical results, calculating the Factor of Safety (FOS) and identifying the maximum displacement. This step verified the design’s margin of error and structural reliability against material yield strength, ensuring compliance (S_R4).

Final Deliverable & Insight

Delivered the complete simulation project files, a formal validation report, and clear, actionable insights into the brake rotor’s structural reliability, confirming the suitability of the client’s theoretical design.

What the Client Shared About This Project

Every project is complete once the results match what the client envisioned. Here’s their perspective on the process, communication, and final outcome.

I needed hard data to back up my design thesis. Touseef delivered more than just a simulation; I received a full structural analysis report checking displacement and FOS. The process was fast, and the ANSYS data was crystal clear. It allowed me to validate my theoretical model perfectly.

Kwame Mensah

Automotive Engineering Student

Have We Worked Together?

You can share your experience and help others understand what it’s like to collaborate with me on engineering projects.

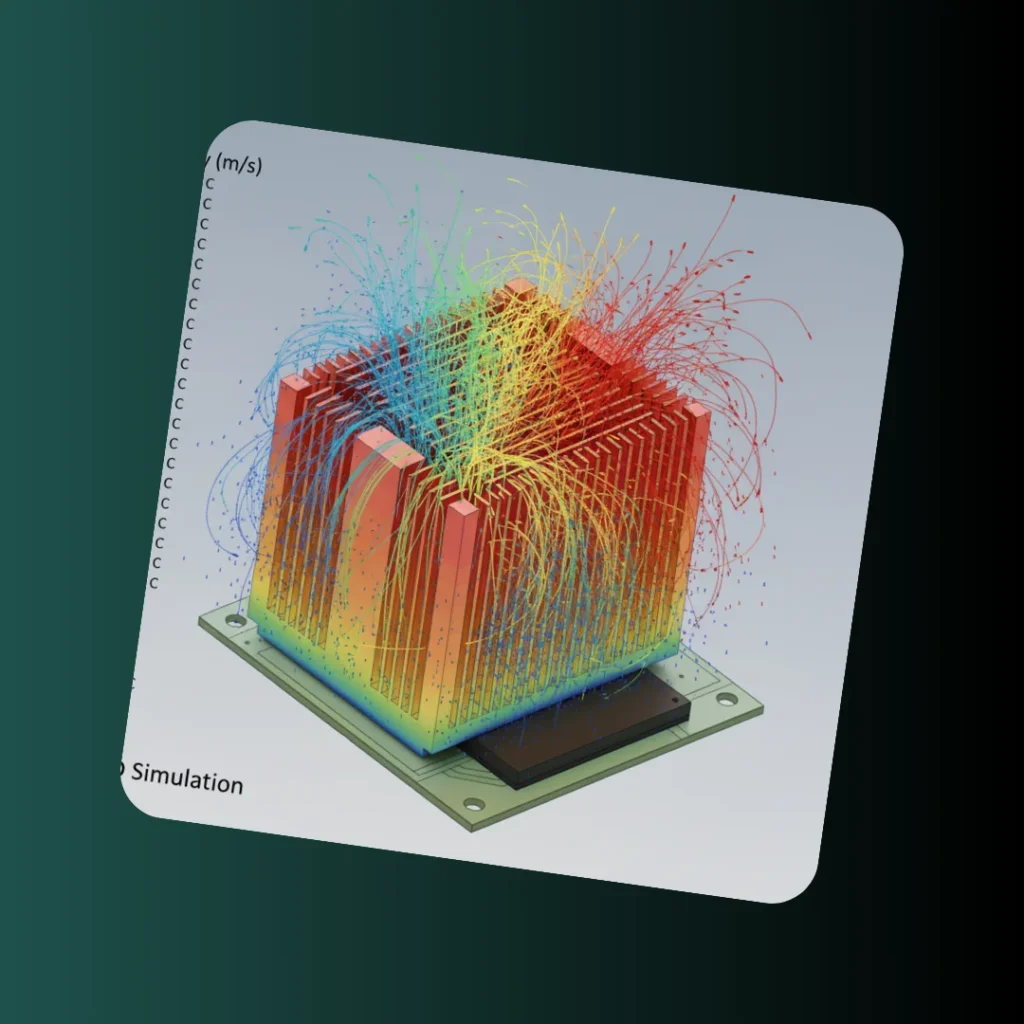

Thermal Management: Optimizing Heat Sink Design for Electronics Reliability

The objective was to design and validate an optimized heat sink to ensure a critical electronic component (e.g., CPU, power transistor) operates within safe thermal limits. This project utilized ANSYS …

Analysis SoftwareANSYS Steady ThermalThermal ComplianceVerified Max TemperatureCooling PerformanceHeat Dissipation OptimizedFin GeometryDesign Iterations Checked

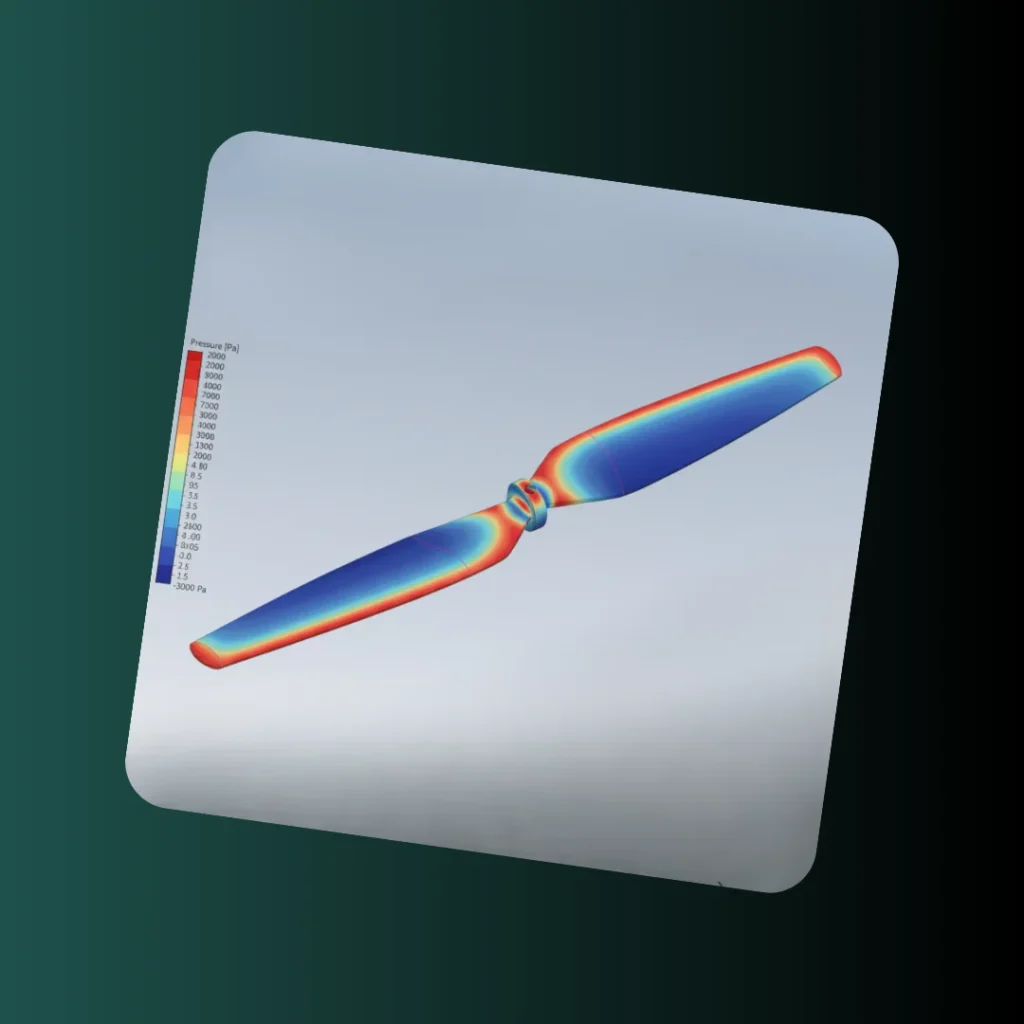

Aerodynamic Optimization: Enhancing Drone Propeller Thrust and Efficiency

The objective was to optimize a drone propeller blade design using advanced CFD analysis to maximize thrust and efficiency under various flight conditions. This project utilized ANSYS Fluent to model …

Efficiency GoalMaximize Thrust/TorqueAnalysis SoftwareANSYS Fluent CFDFlow ModelingComplex Airflow SolvedOptimization FocusAerodynamic Efficiency

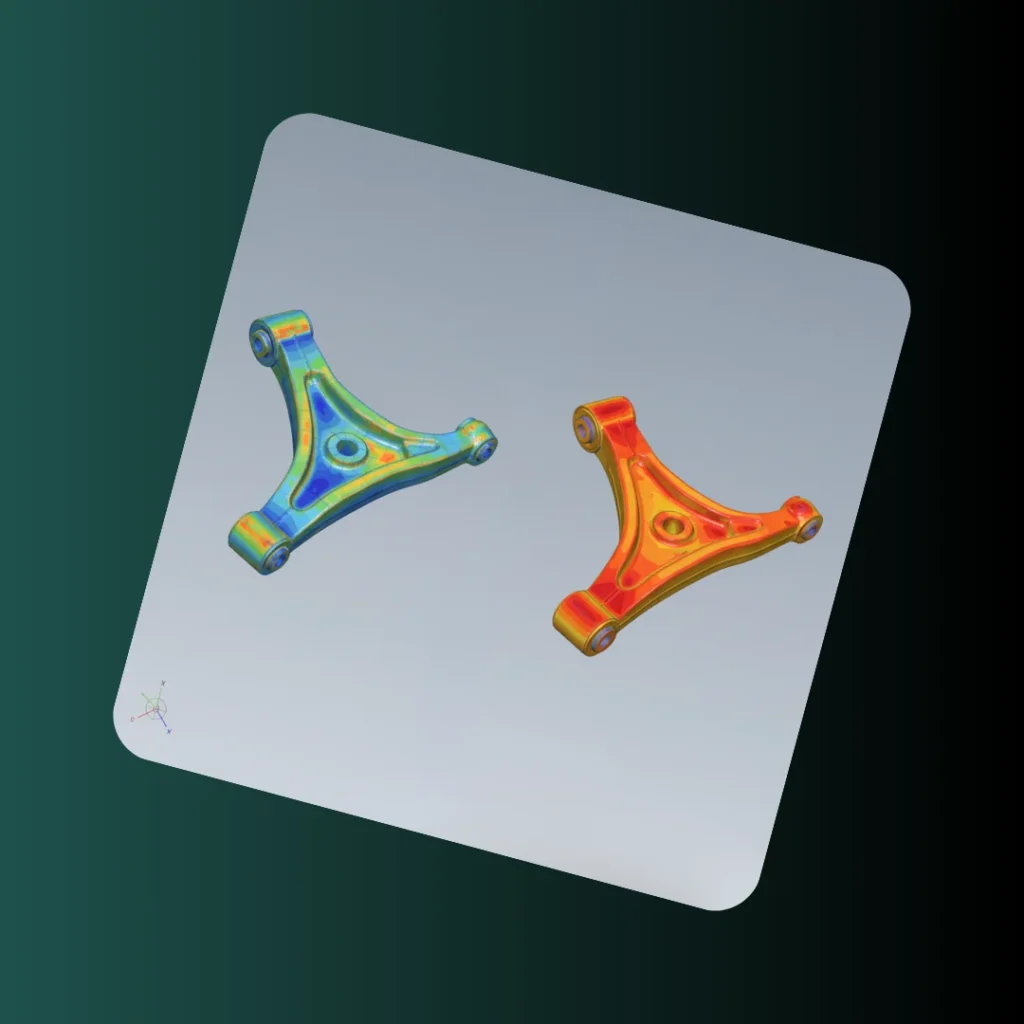

Structural Reliability Audit: Reverse Engineering of Suspension Component

The objective was to take a client’s legacy engineering drawing of an automotive suspension component and perform a detailed structural FEA verification under simulated operating loads. This project utilized 2D-to-3D …

Data OriginEngineering Drawing DataReliability MetricFactor of SafetyVerification MethodSimulated Load TestingDesign StatusVerified Safety Critical

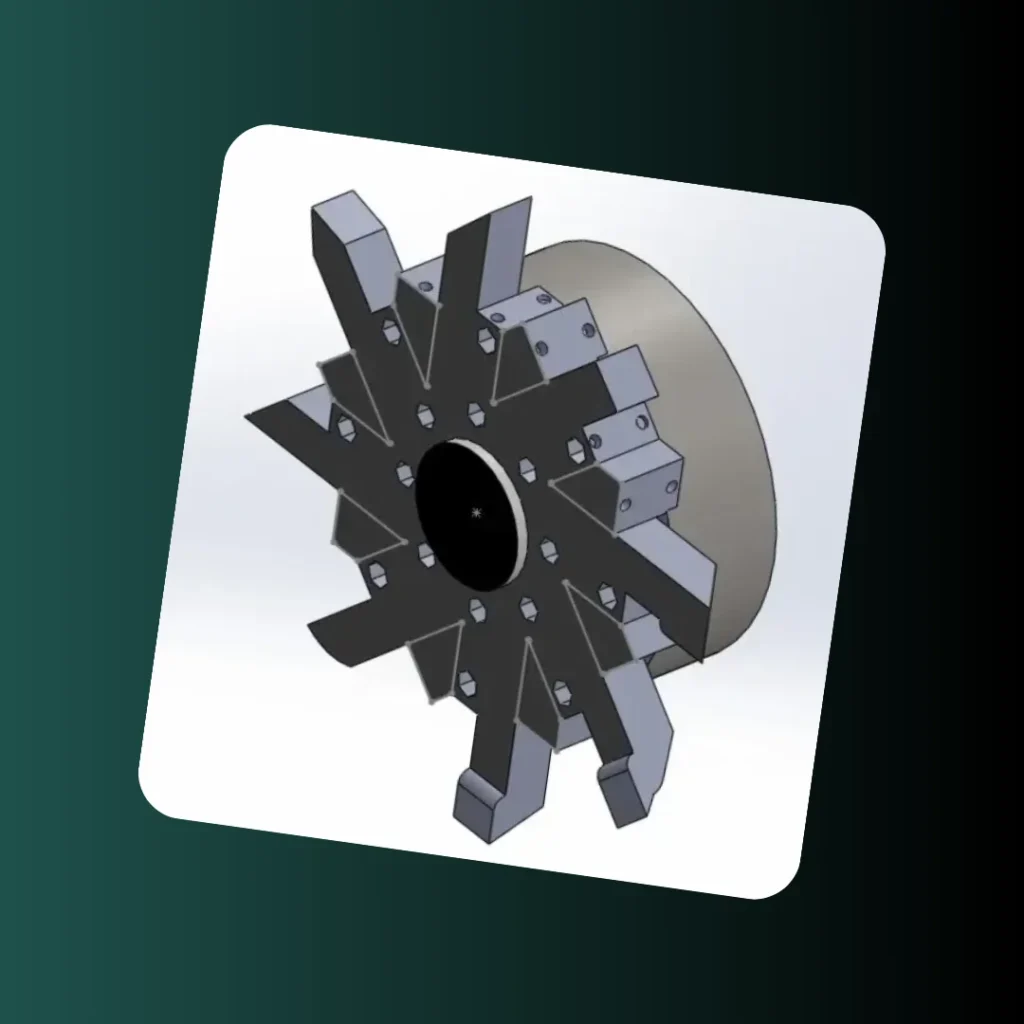

CNC Tool Turret: High-Precision Assembly and Indexing Verification

The requirement was to create a precise, high-fidelity 3D CAD model for a CNC machine tool turret assembly, ensuring the accurate rotational mating and precise indexing of multiple cutting tools. …

Primary ServicesCAD/DFM / Design ForensicsTool Capacity08 Tool StationsComponent RigidityHigh Structural IntegritySoftware UsedSolidWorks Assembly

High-Fidelity CAD: Accurate Parametric Modeling for Visualization

A client required a high-fidelity 3D CAD model of an industrial machine feed mechanism assembly for use in technical archives and presentations. This project focused on precision parametric modeling and …

Software UsedSolidWorks AssemblyAssembly ComplexityAll Mates VerificationModel Flexibility100% ParametricGeometric AccuracyHigh-Fidelity Output

Have a Project in Mind?

If you’re working on a product, simulation, CAD model, or need engineering support, I’d be happy to help you turn it into something precise and functional.