Design. Simulate. Validate. Real Engineering in Motion.

Explore a collection of projects that showcase how CAD modeling, simulation, and optimization come together to solve real engineering challenges. Each case study highlights a unique problem, the process behind it, and the measurable results achieved through mechanical precision and analytical design.

Mechanical Case Studies That Redefine Precision and Performance

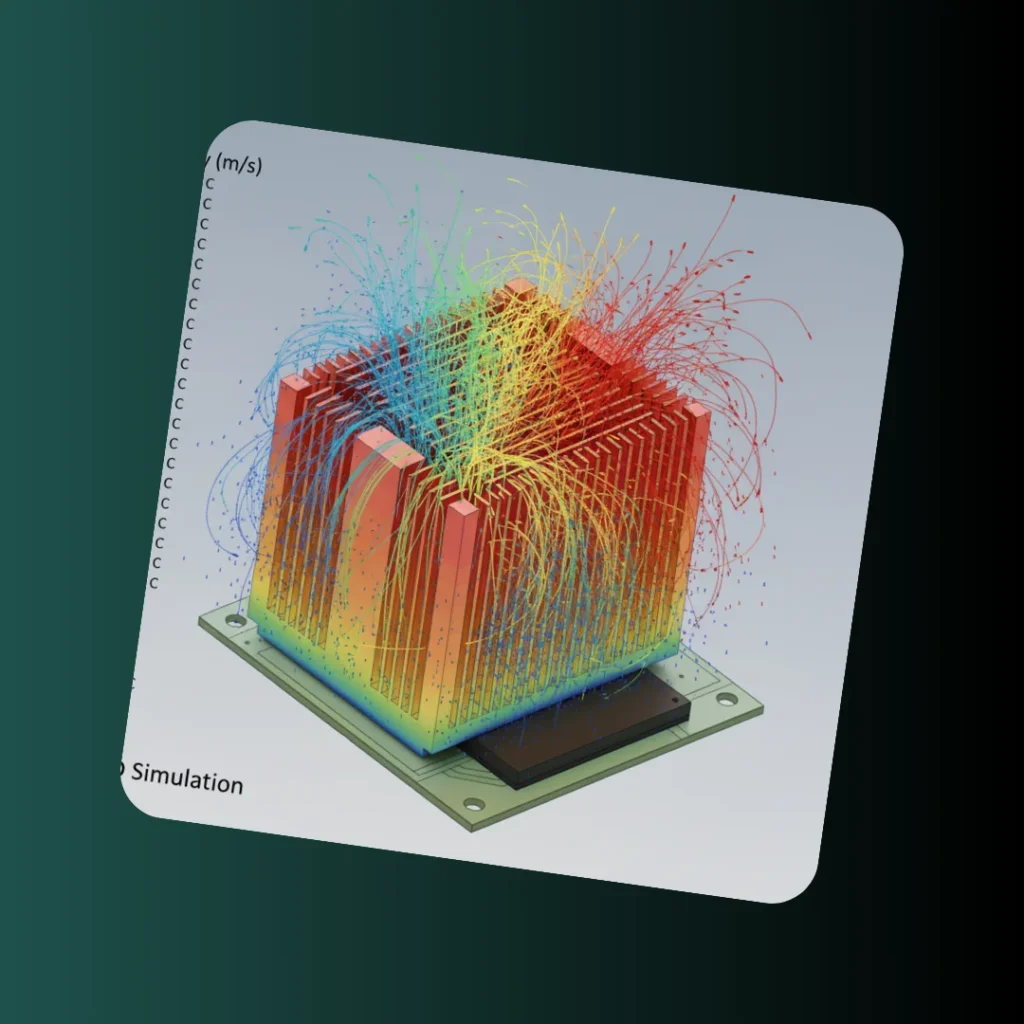

Thermal Management: Optimizing Heat Sink Design for Electronics Reliability

The objective was to design and validate an optimized heat sink to ensure a critical electronic component (e.g., CPU, power transistor) operates within safe thermal limits. This project utilized ANSYS …

Analysis SoftwareANSYS Steady ThermalThermal ComplianceVerified Max TemperatureCooling PerformanceHeat Dissipation OptimizedFin GeometryDesign Iterations Checked

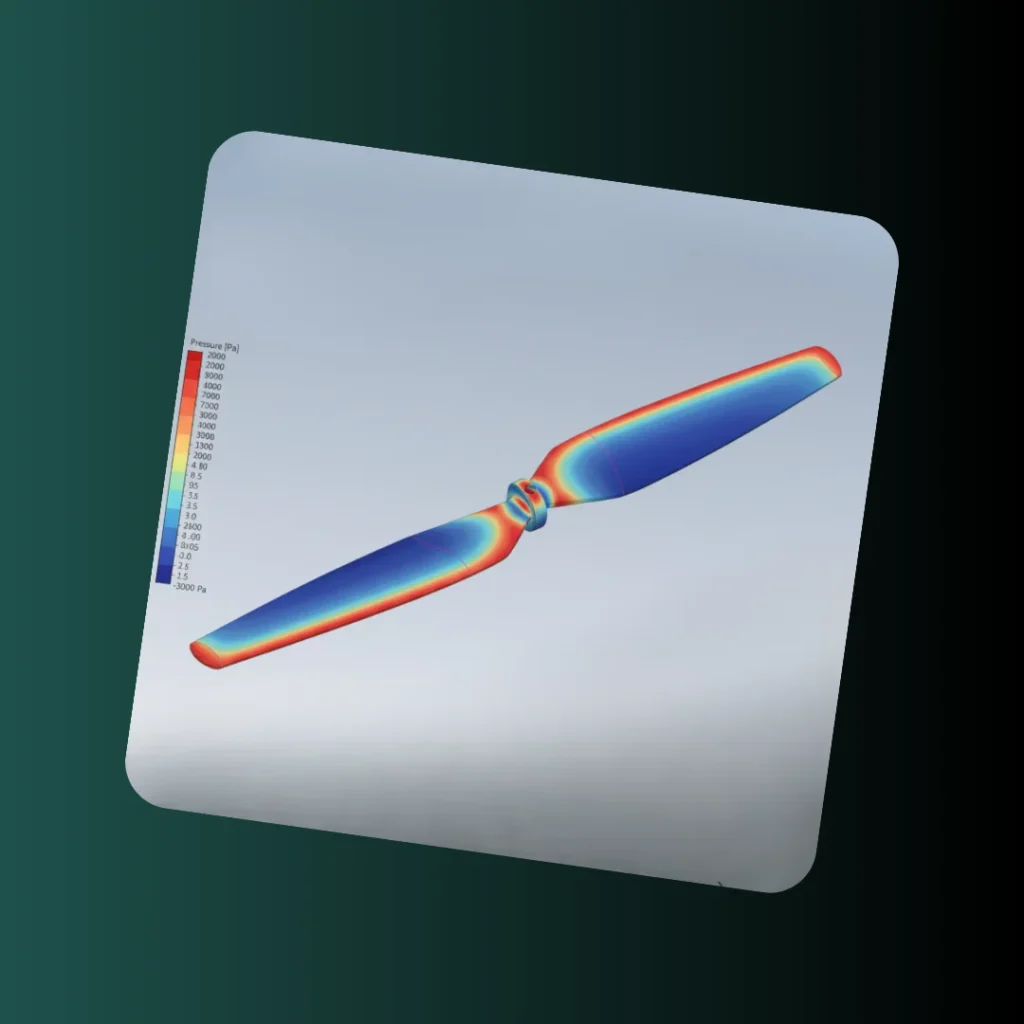

Aerodynamic Optimization: Enhancing Drone Propeller Thrust and Efficiency

The objective was to optimize a drone propeller blade design using advanced CFD analysis to maximize thrust and efficiency under various flight conditions. This project utilized ANSYS Fluent to model …

Efficiency GoalMaximize Thrust/TorqueAnalysis SoftwareANSYS Fluent CFDFlow ModelingComplex Airflow SolvedOptimization FocusAerodynamic Efficiency

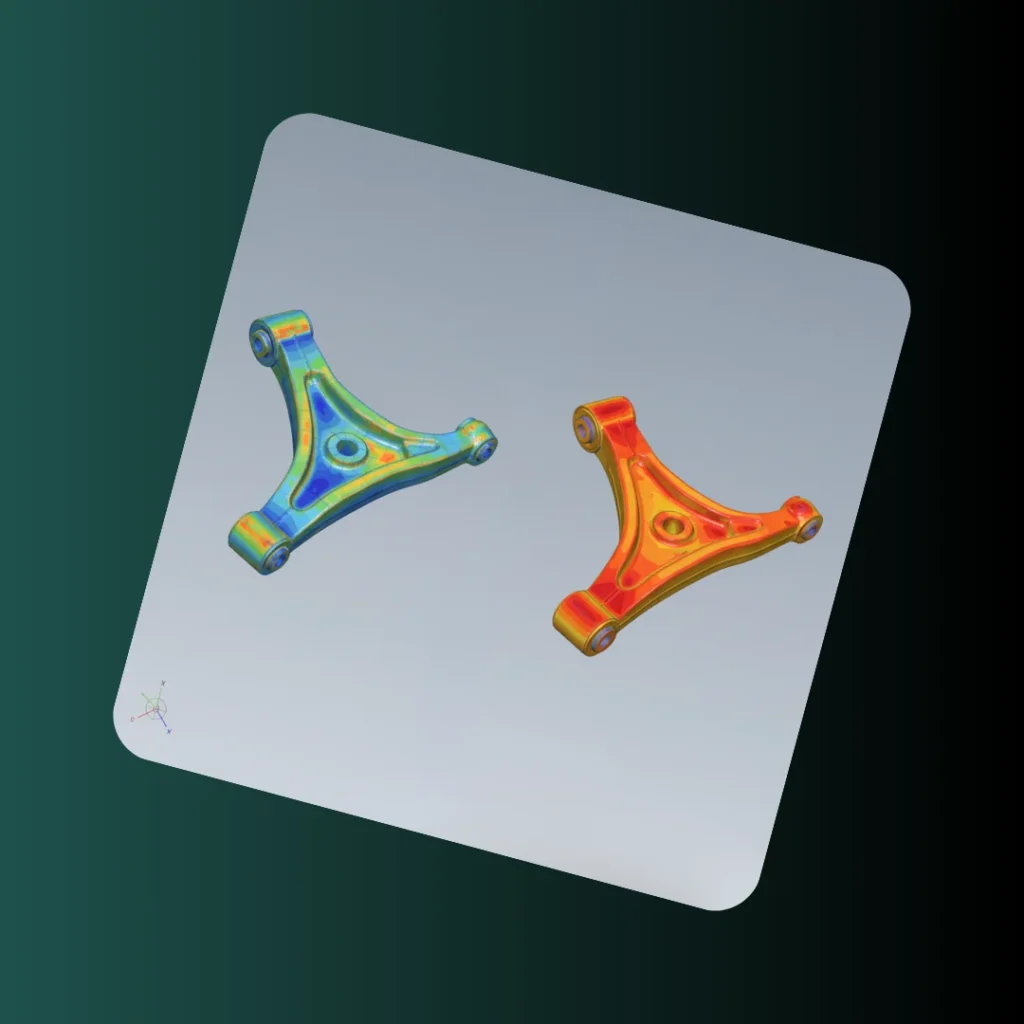

Structural Reliability Audit: Reverse Engineering of Suspension Component

The objective was to take a client’s legacy engineering drawing of an automotive suspension component and perform a detailed structural FEA verification under simulated operating loads. This project utilized 2D-to-3D …

Data OriginEngineering Drawing DataReliability MetricFactor of SafetyVerification MethodSimulated Load TestingDesign StatusVerified Safety Critical

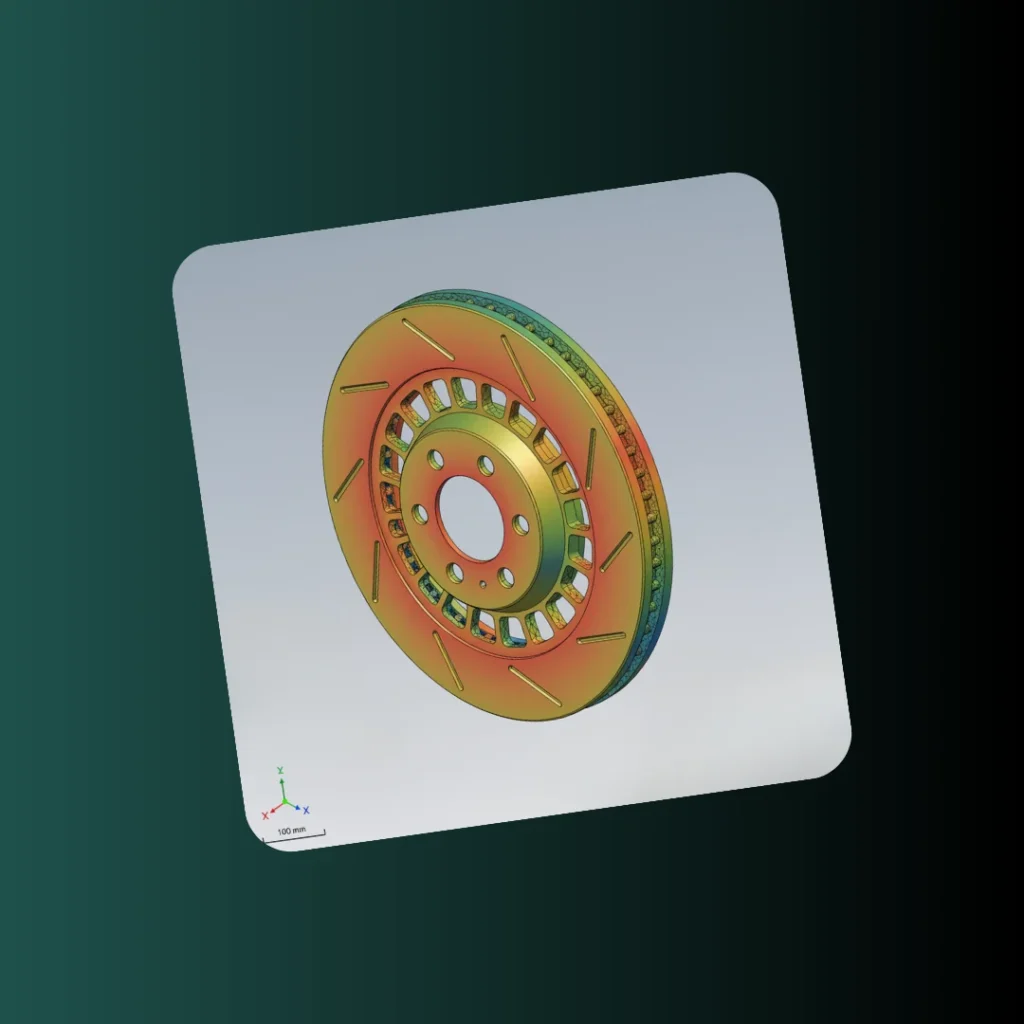

Static Structural Analysis: Verifying Automotive Brake Rotor Reliability

The client needed to model their theoretical brake rotor design and verify its performance under maximum load conditions. This project utilized SolidWorks CAD modeling and ANSYS Static Structural analysis to …

Analysis SoftwareANSYS Static StructuralCritical ResultStress/Strain CheckedReliability MetricFactor of SafetyDesign StatusVerified Reliable

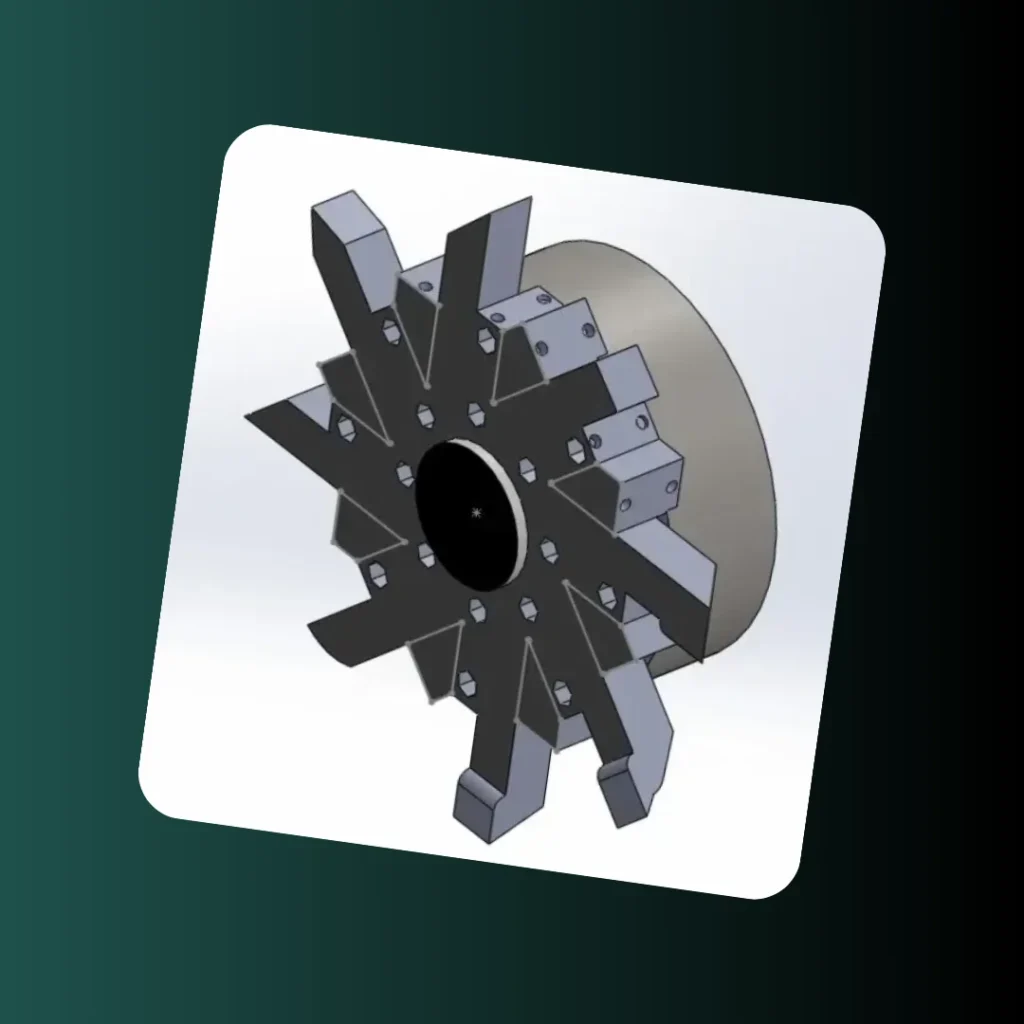

CNC Tool Turret: High-Precision Assembly and Indexing Verification

The requirement was to create a precise, high-fidelity 3D CAD model for a CNC machine tool turret assembly, ensuring the accurate rotational mating and precise indexing of multiple cutting tools. …

Primary ServicesCAD/DFM / Design ForensicsTool Capacity08 Tool StationsComponent RigidityHigh Structural IntegritySoftware UsedSolidWorks Assembly

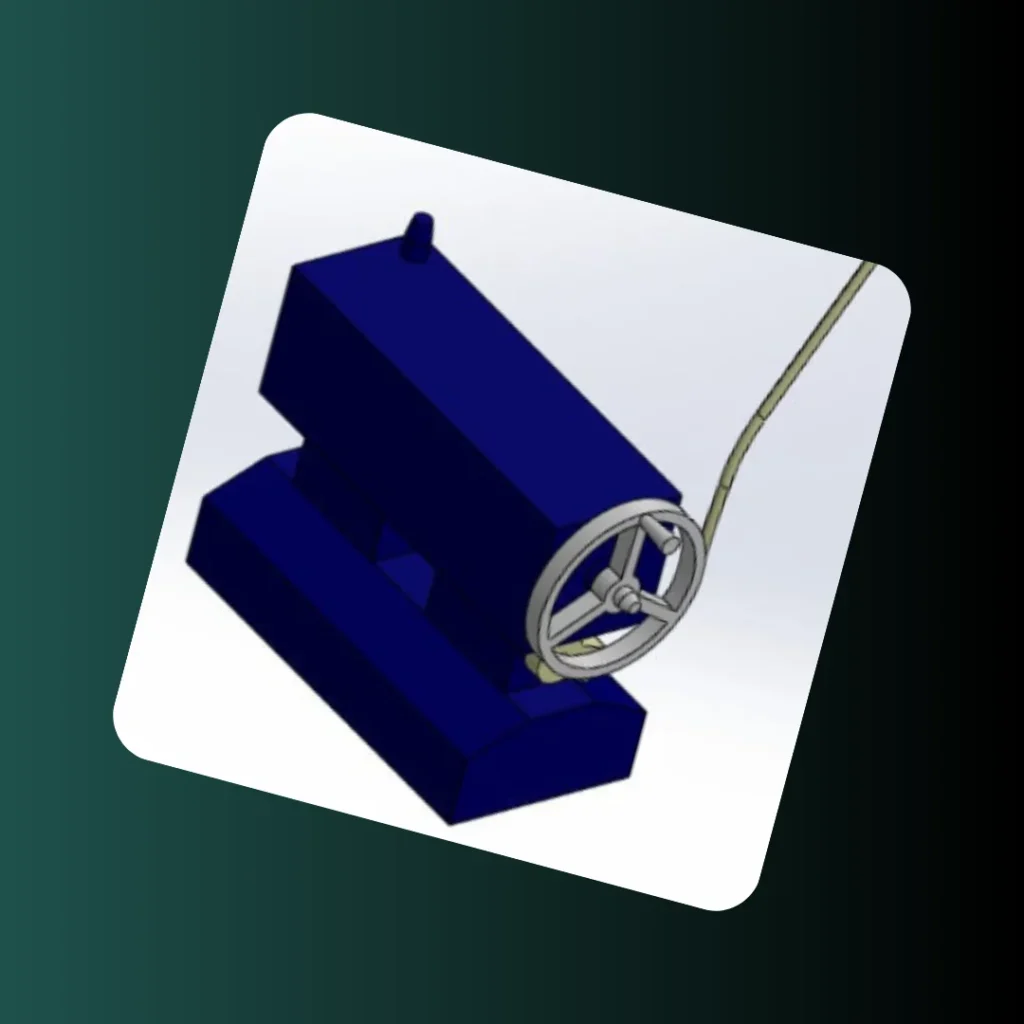

High-Fidelity CAD: Accurate Parametric Modeling for Visualization

A client required a high-fidelity 3D CAD model of an industrial machine feed mechanism assembly for use in technical archives and presentations. This project focused on precision parametric modeling and …

Software UsedSolidWorks AssemblyAssembly ComplexityAll Mates VerificationModel Flexibility100% ParametricGeometric AccuracyHigh-Fidelity Output

Have a Project in Mind? Let’s Build Something That Performs.

You’ve seen the results, now let’s talk about how we can create yours. I’m open to new collaborations, whether it’s design, simulation, or research-based engineering. Share your idea, and I’ll help shape it into a tested solution ready for real conditions.

Let’s Clear Things Up

What type of projects are included in your case studies?

My case studies cover CAD modeling, design validation, and simulation-driven optimization. Each project focuses on solving real mechanical challenges and delivering measurable performance improvements.

Do your case studies include both academic and industry projects?

Yes, they include both. I’ve worked on industry-level projects as well as research-driven studies that explore engineering innovation through simulation and system analysis.

How do you approach a new mechanical design project?

Every project begins with understanding the core problem, followed by concept modeling, simulation testing, and refinement. The result is a design that performs efficiently under actual working conditions.

Can clients request detailed insights into a specific case study?

Of course. If you’d like to learn more about a particular project or method, you can contact me directly, and I’ll share the technical overview or relevant performance results.

What tools do you use for simulation and analysis?

I primarily use SolidWorks, ANSYS, and AutoDesk for CAD and simulation. These tools allow accurate performance prediction, stress analysis, and design optimization.

How are your case studies structured?

Each case study explains the challenge, approach, process, and results. It’s designed to show the complete engineering workflow, not just the final outcome.

Do you share confidential client information in your case studies?

Never. All shared work is approved by clients and stripped of any sensitive data. I only present technical processes and results that highlight the engineering value.

Can you replicate the same process for my project?

Yes, every process I use is adaptable. The same simulation-based workflow can be tailored to your requirements, regardless of project size or industry.