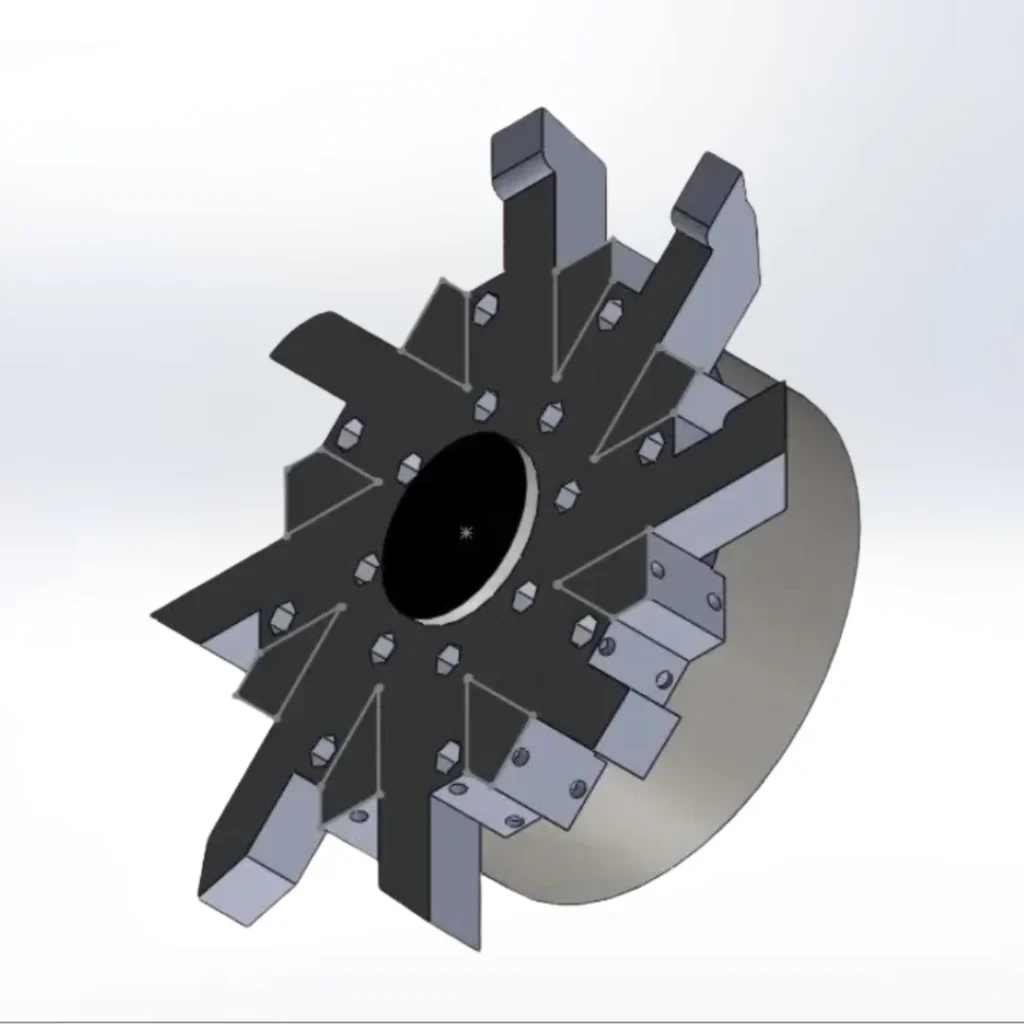

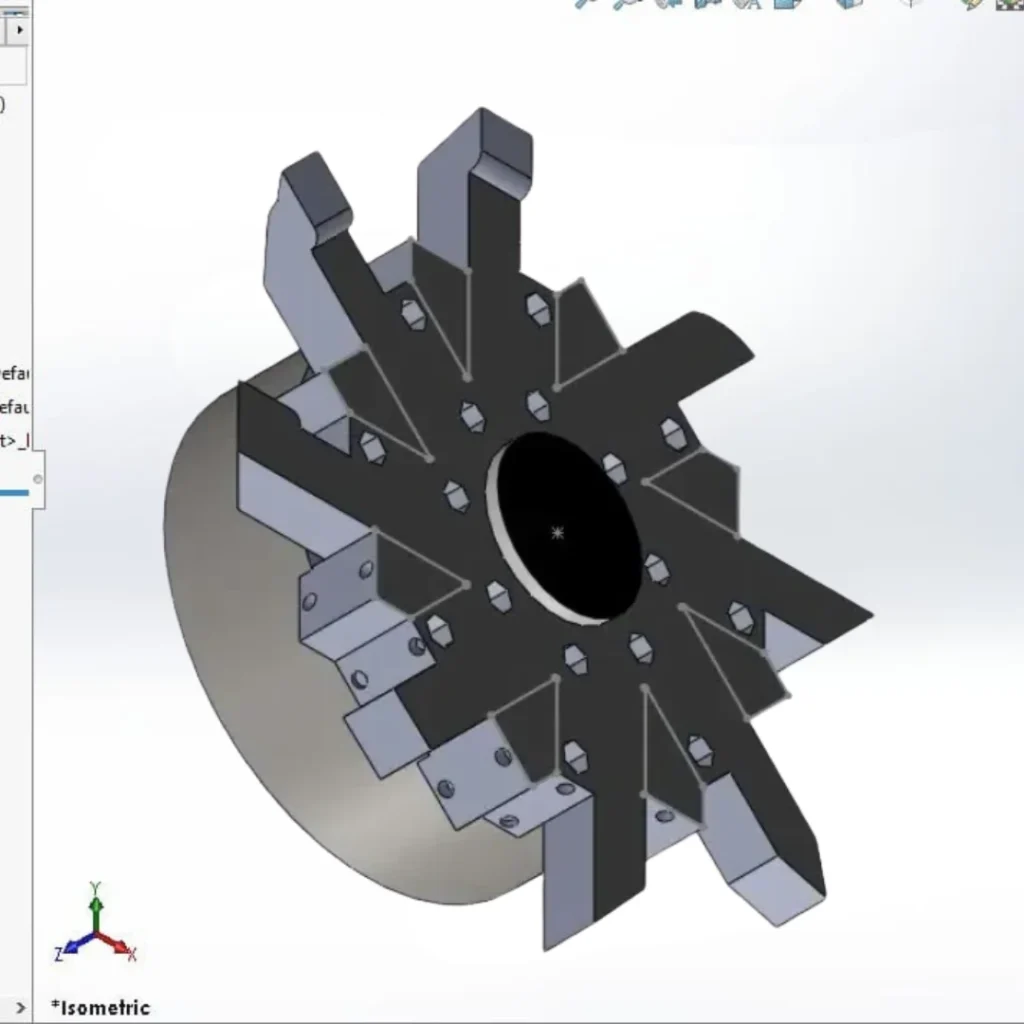

CNC Tool Turret: High-Precision Assembly and Indexing Verification

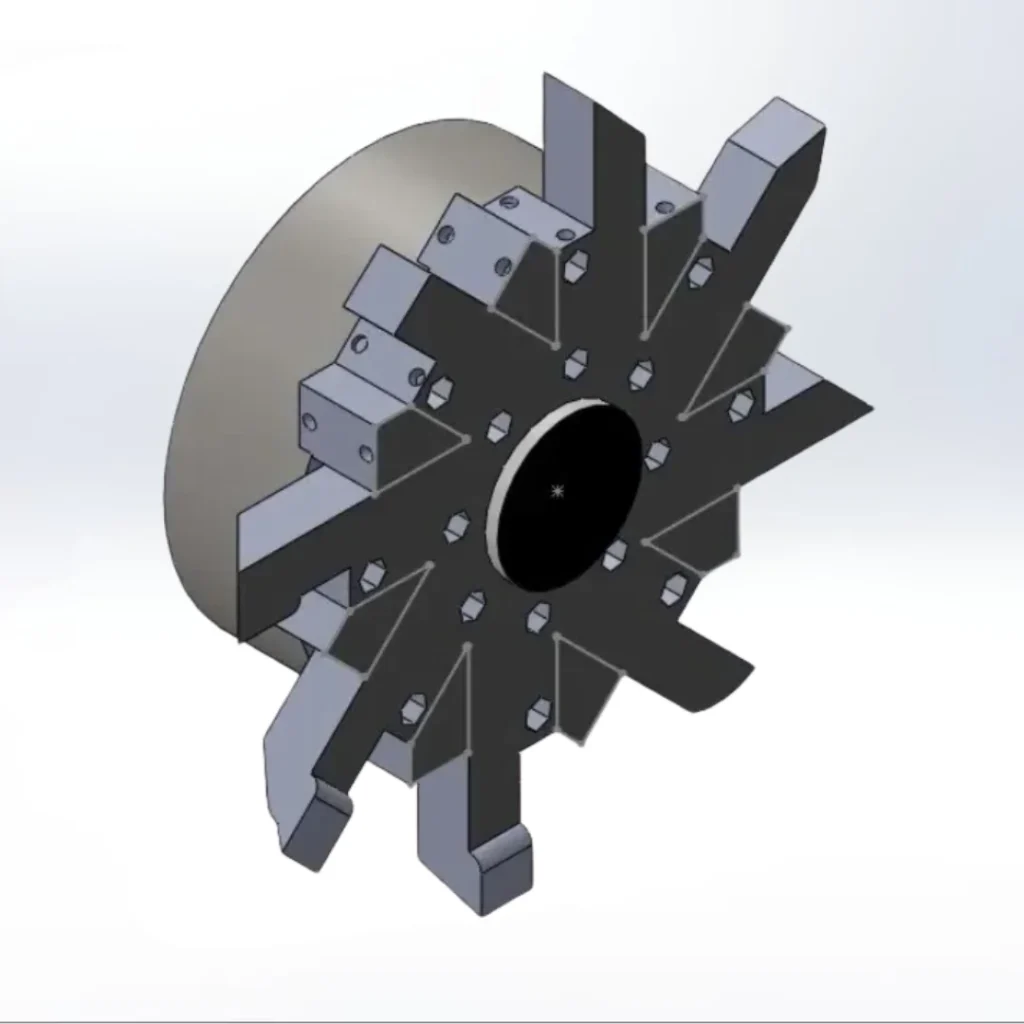

The requirement was to create a precise, high-fidelity 3D CAD model for a CNC machine tool turret assembly, ensuring the accurate rotational mating and precise indexing of multiple cutting tools. This dual-focus project combined precision parametric modeling with analytical reconstruction to guarantee structural rigidity and zero positional error for manufacturing implementation.

How This Project Took Shape Step by Step

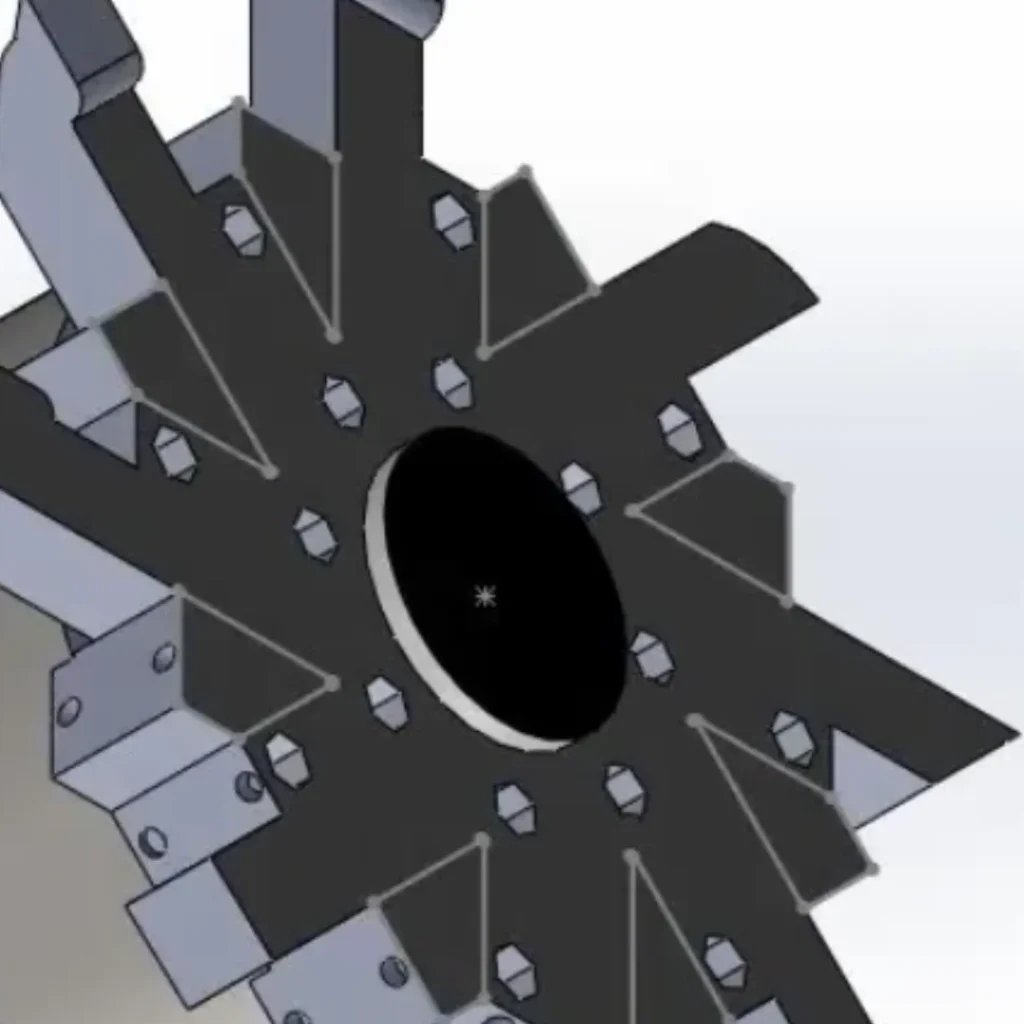

High-Fidelity Part Modeling

Created clean, detailed 3D CAD models for all individual components, including the main hub and the multiple tool holders. Robust construction techniques were utilized to ensure geometric integrity, which is essential for components that undergo heavy industrial loads during high-speed machining operations (S_R2).

Rotational Assembly Mating

Defined and verified the crucial rotational and positional mates between the hub and the tool holders in the SolidWorks assembly environment. This ensures the digital mechanism accurately simulates the smooth, precise indexing required for CNC operations and guarantees correct alignment during use.

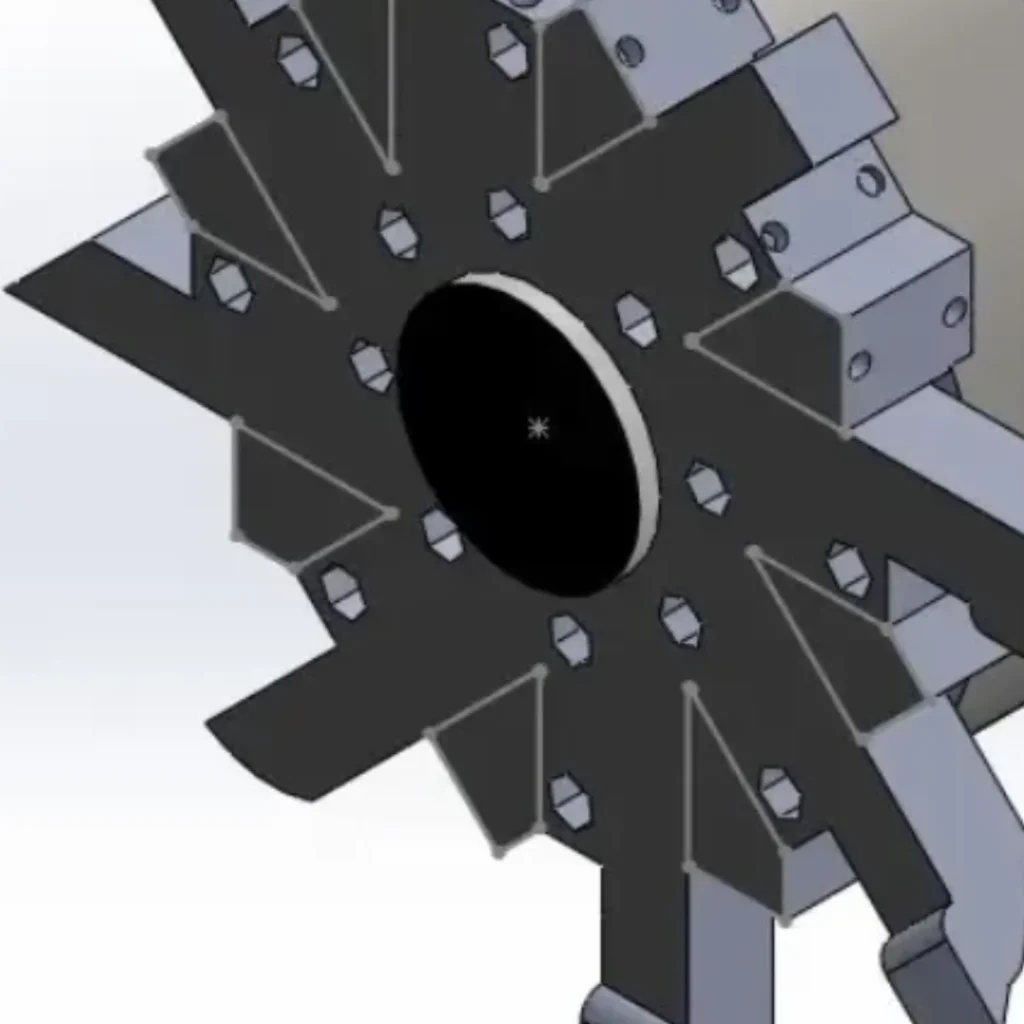

Dimensional & Tolerance Audit

Performed a rigorous dimensional integrity check of all interface fits and clearances, confirming the geometry met the tight industrial tolerances required for CNC machine components. This meticulous auditing is critical for preventing wear and tear during rapid tool changes.

DFM Feasibility & Optimization

Audited the complex structure to ensure all features were accessible for high-precision machining and optimized the overall hub geometry. This proactive DFM check reduces manufacturing complexity and minimizes waste during the fabrication of the mission-critical hub.

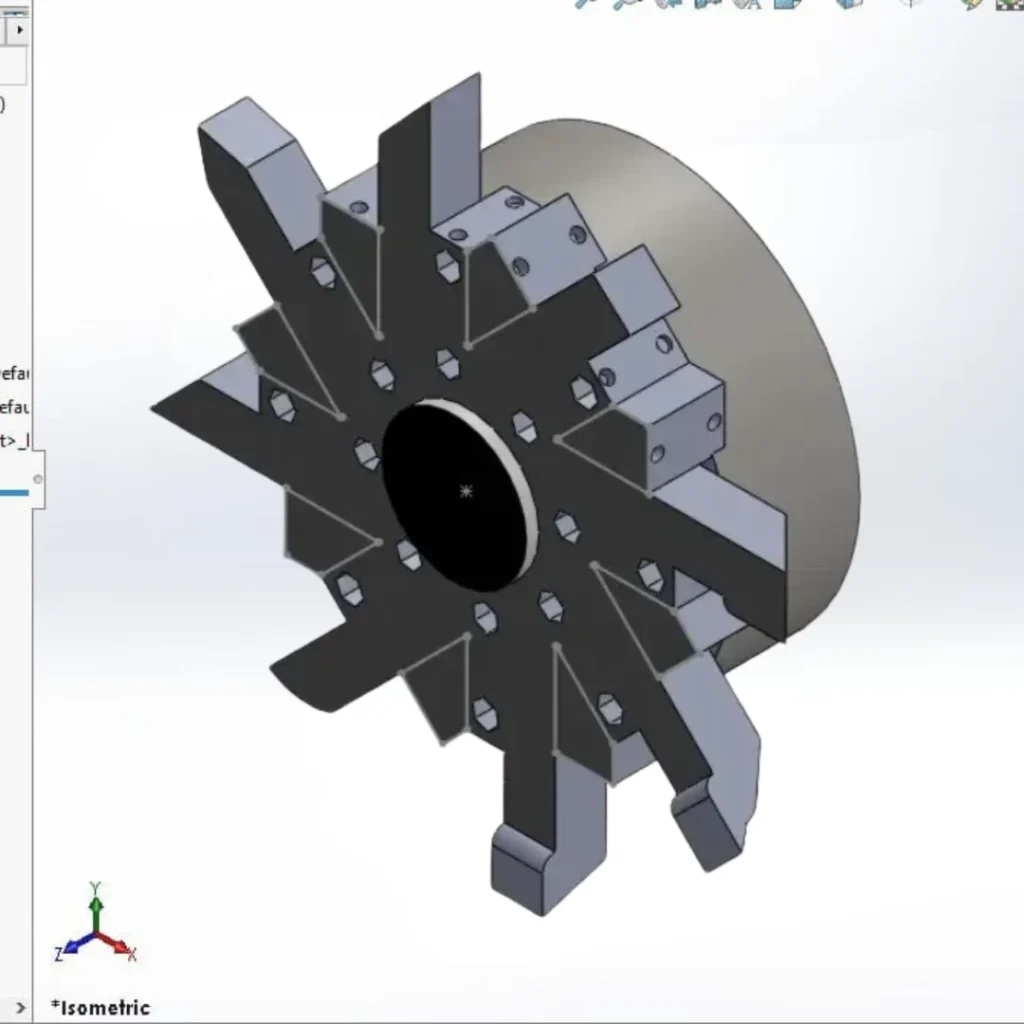

Analytical Reconstruction Setup

Established the virtual environment to perform proactive troubleshooting and analyze potential rotational interference or structural weaknesses, ensuring the component’s long-term structural reliability (S_R15).

Final CAM-Ready Handover

Delivered the native SolidWorks CAD files and neutral formats, along with documentation of the critical mating checks, ensuring the entire component was verified and guaranteed CAM-ready for specialized industrial manufacturing.

What the Client Shared About This Project

Every project is complete once the results match what the client envisioned. Here’s their perspective on the process, communication, and final outcome.

Working on a mission-critical part like a tool turret requires more than just modeling, it needs verified indexing accuracy. The engineer’s detailed rotational mating verification saved us from potential indexing failures on the machine. The geometry delivered was robust and completely CAM-ready.

Darren Hayes

CNC Systems Engineer

Have We Worked Together?

You can share your experience and help others understand what it’s like to collaborate with me on engineering projects.

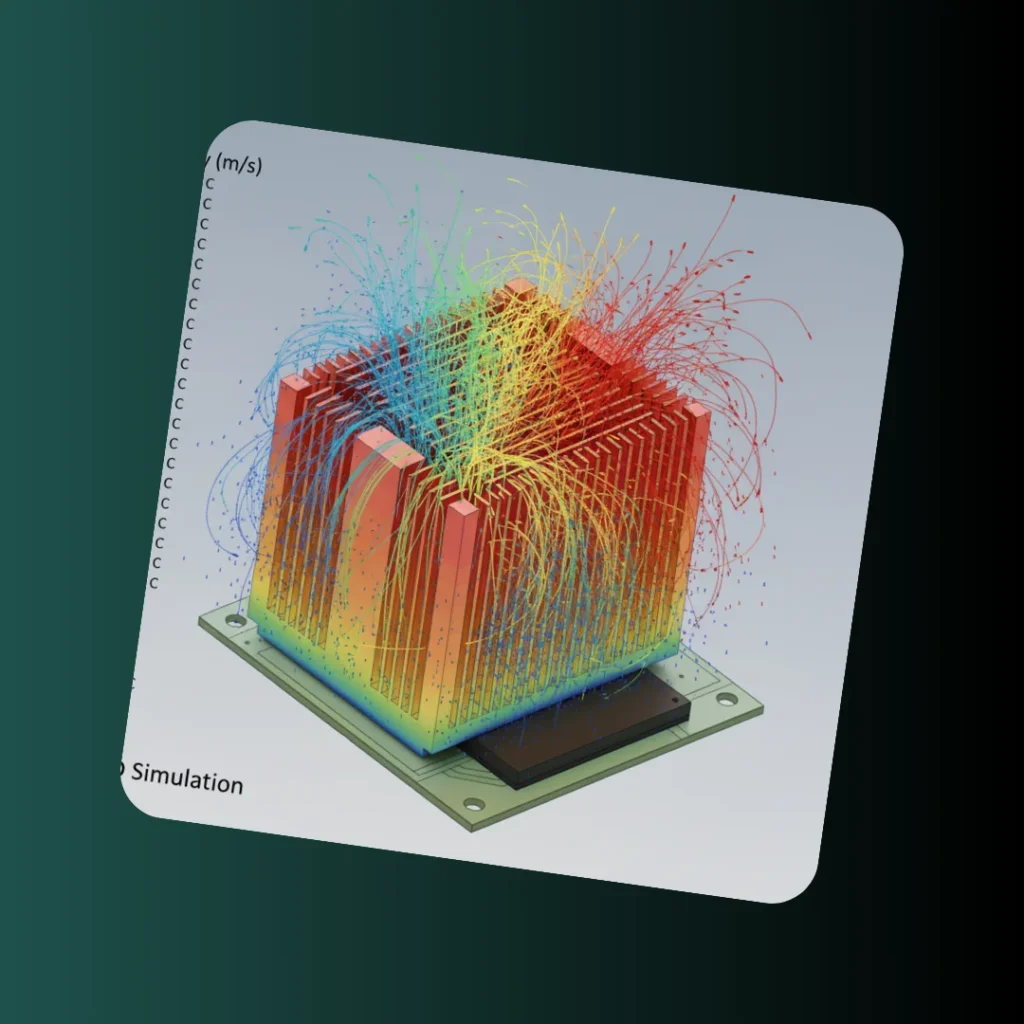

Thermal Management: Optimizing Heat Sink Design for Electronics Reliability

The objective was to design and validate an optimized heat sink to ensure a critical electronic component (e.g., CPU, power transistor) operates within safe thermal limits. This project utilized ANSYS …

Analysis SoftwareANSYS Steady ThermalThermal ComplianceVerified Max TemperatureCooling PerformanceHeat Dissipation OptimizedFin GeometryDesign Iterations Checked

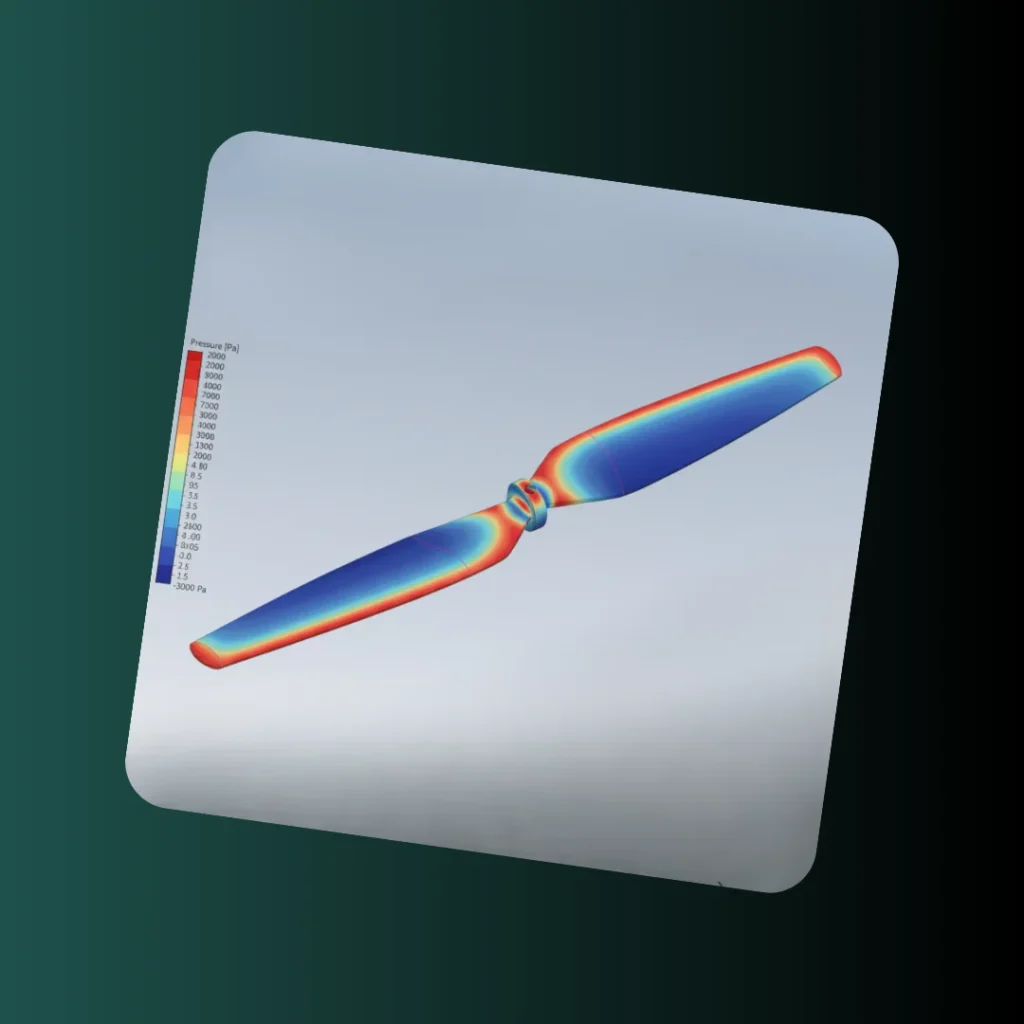

Aerodynamic Optimization: Enhancing Drone Propeller Thrust and Efficiency

The objective was to optimize a drone propeller blade design using advanced CFD analysis to maximize thrust and efficiency under various flight conditions. This project utilized ANSYS Fluent to model …

Efficiency GoalMaximize Thrust/TorqueAnalysis SoftwareANSYS Fluent CFDFlow ModelingComplex Airflow SolvedOptimization FocusAerodynamic Efficiency

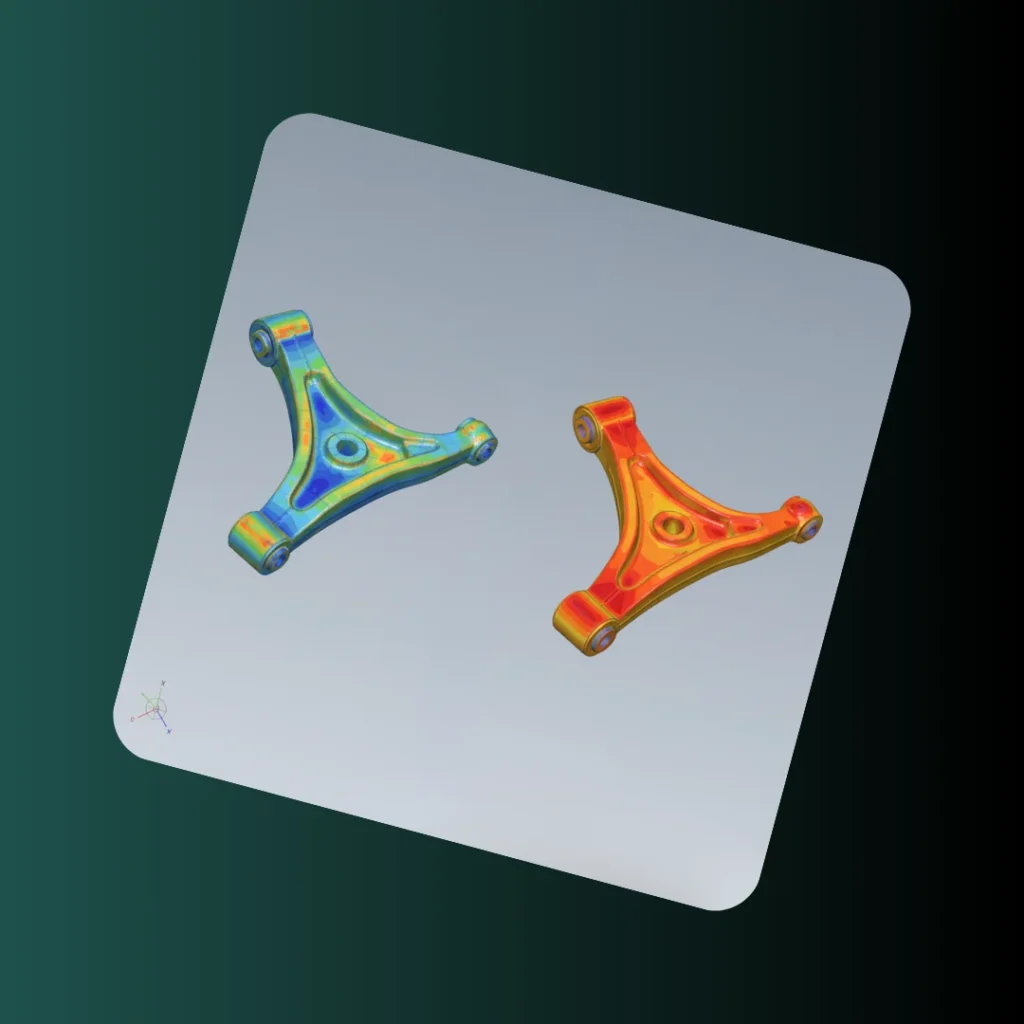

Structural Reliability Audit: Reverse Engineering of Suspension Component

The objective was to take a client’s legacy engineering drawing of an automotive suspension component and perform a detailed structural FEA verification under simulated operating loads. This project utilized 2D-to-3D …

Data OriginEngineering Drawing DataReliability MetricFactor of SafetyVerification MethodSimulated Load TestingDesign StatusVerified Safety Critical

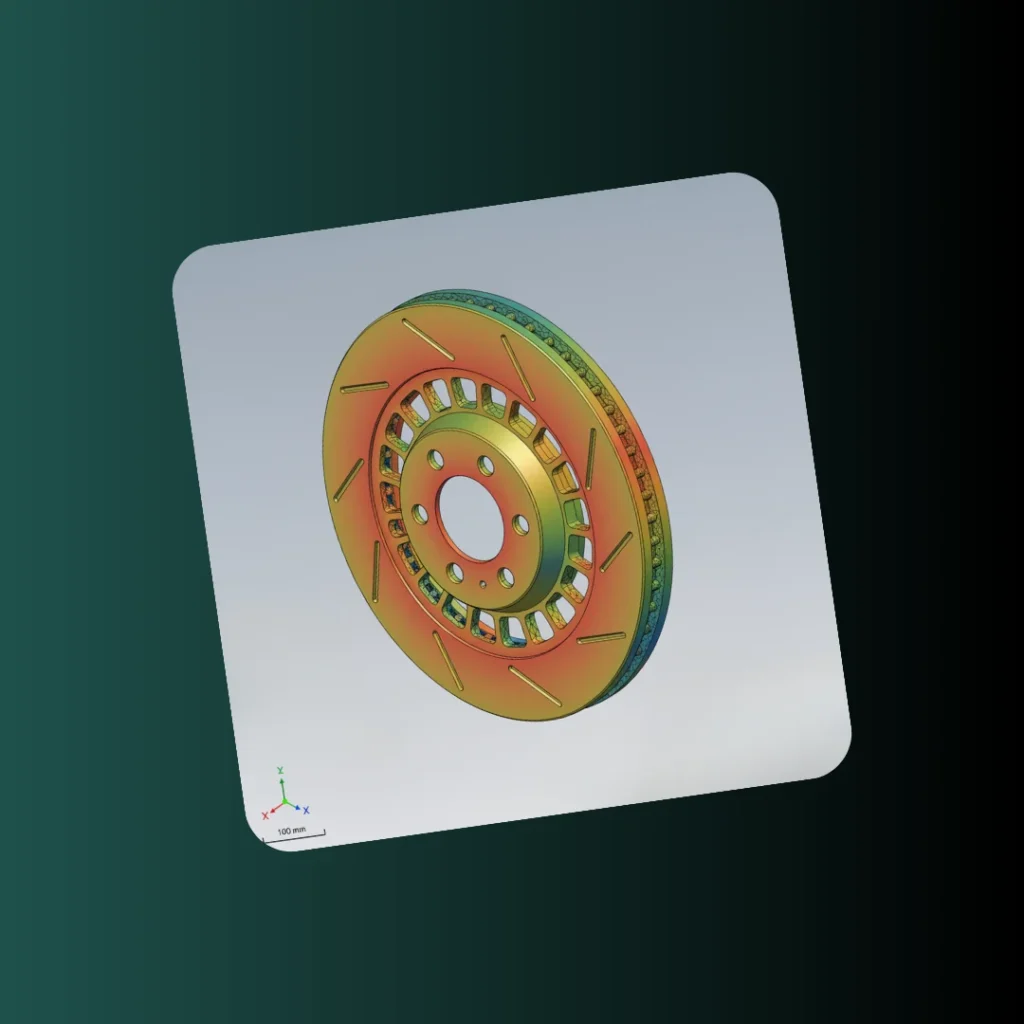

Static Structural Analysis: Verifying Automotive Brake Rotor Reliability

The client needed to model their theoretical brake rotor design and verify its performance under maximum load conditions. This project utilized SolidWorks CAD modeling and ANSYS Static Structural analysis to …

Analysis SoftwareANSYS Static StructuralCritical ResultStress/Strain CheckedReliability MetricFactor of SafetyDesign StatusVerified Reliable

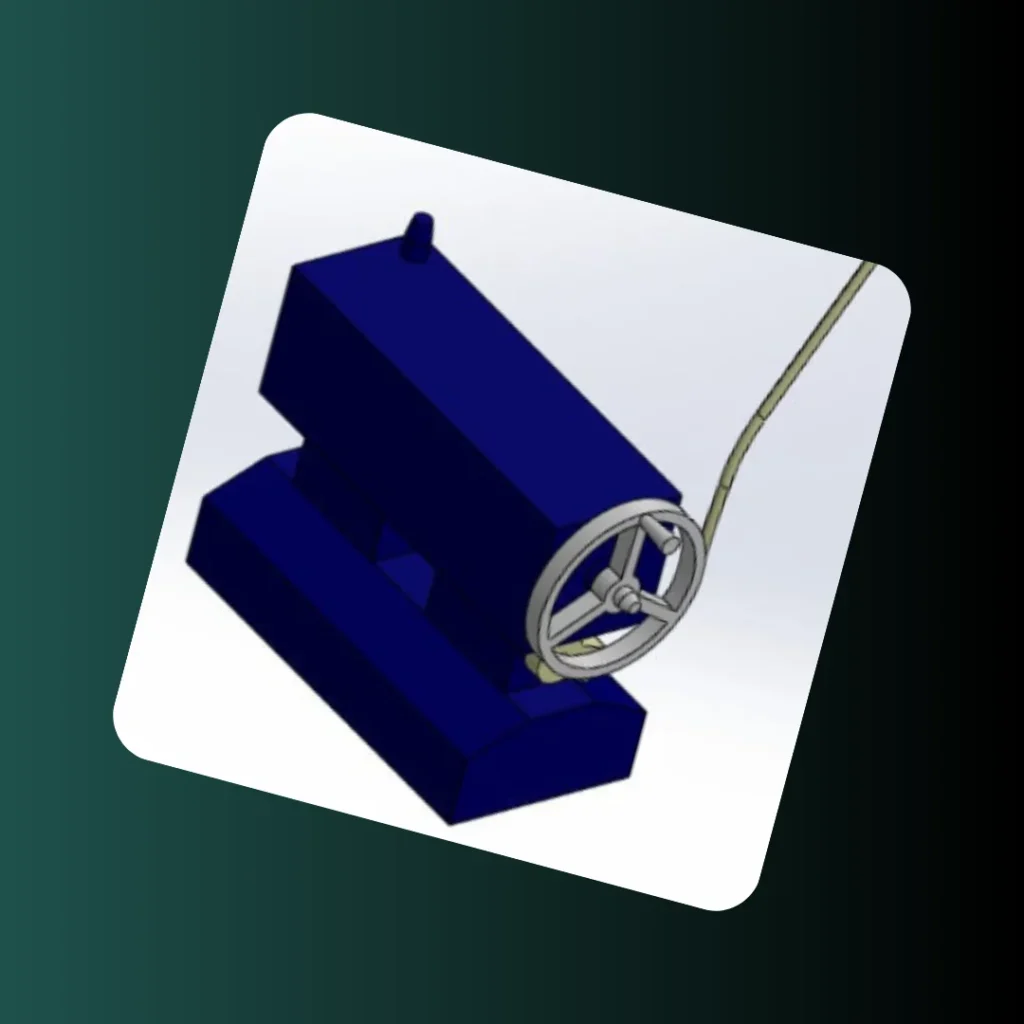

High-Fidelity CAD: Accurate Parametric Modeling for Visualization

A client required a high-fidelity 3D CAD model of an industrial machine feed mechanism assembly for use in technical archives and presentations. This project focused on precision parametric modeling and …

Software UsedSolidWorks AssemblyAssembly ComplexityAll Mates VerificationModel Flexibility100% ParametricGeometric AccuracyHigh-Fidelity Output

Have a Project in Mind?

If you’re working on a product, simulation, CAD model, or need engineering support, I’d be happy to help you turn it into something precise and functional.