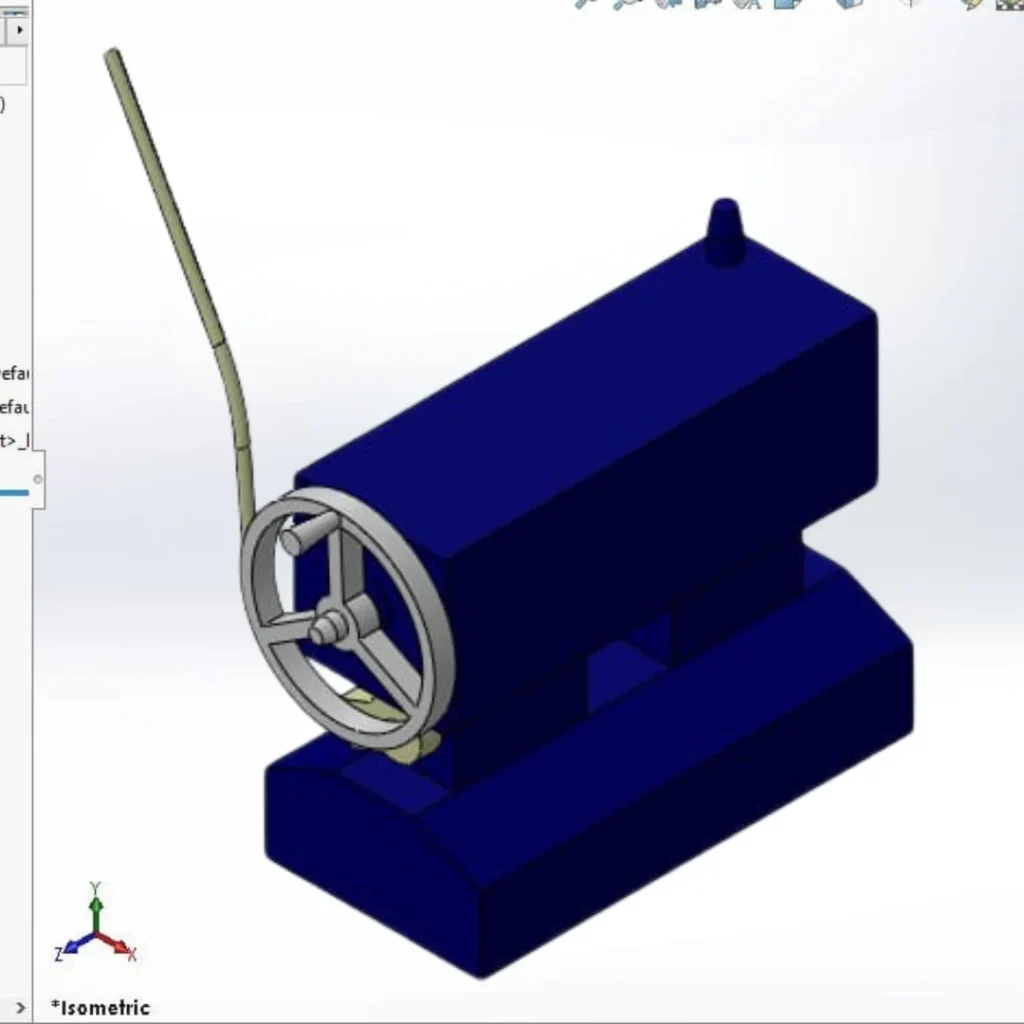

High-Fidelity CAD: Accurate Parametric Modeling for Visualization

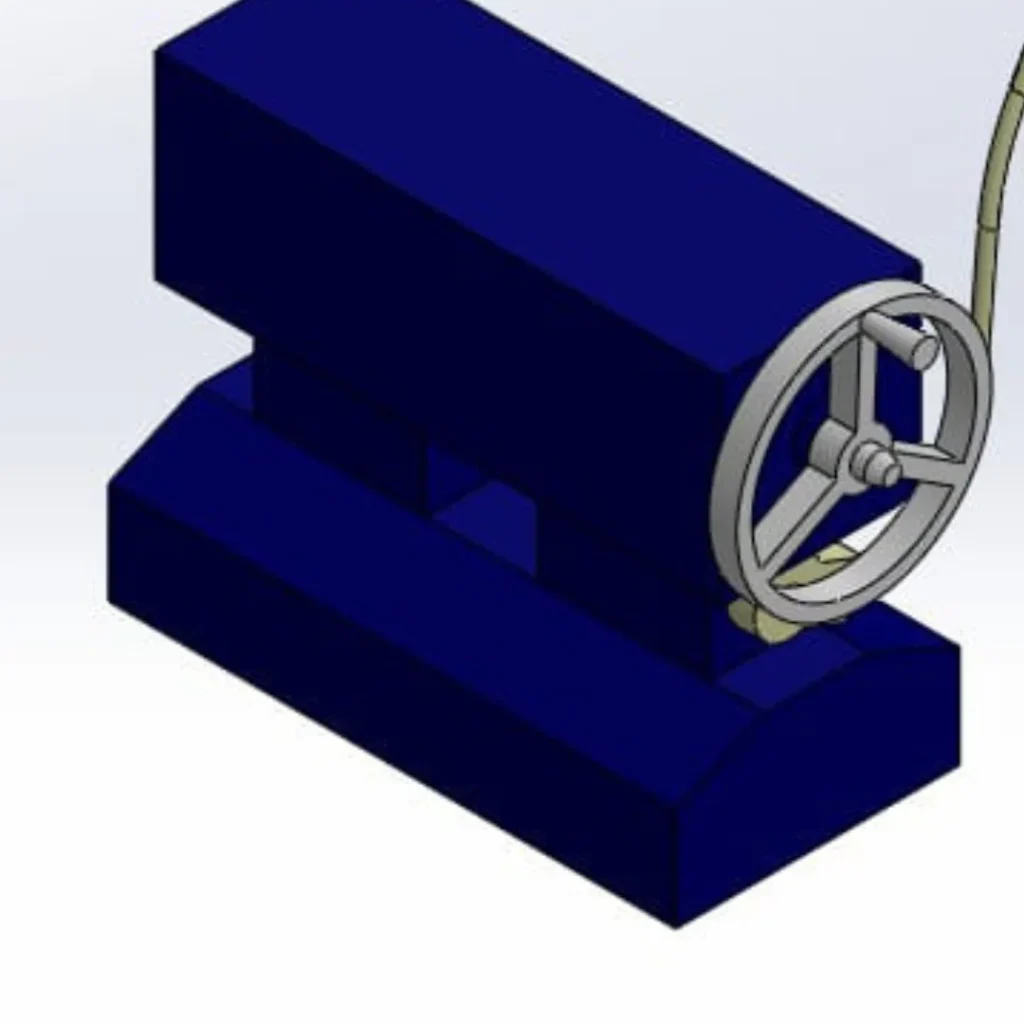

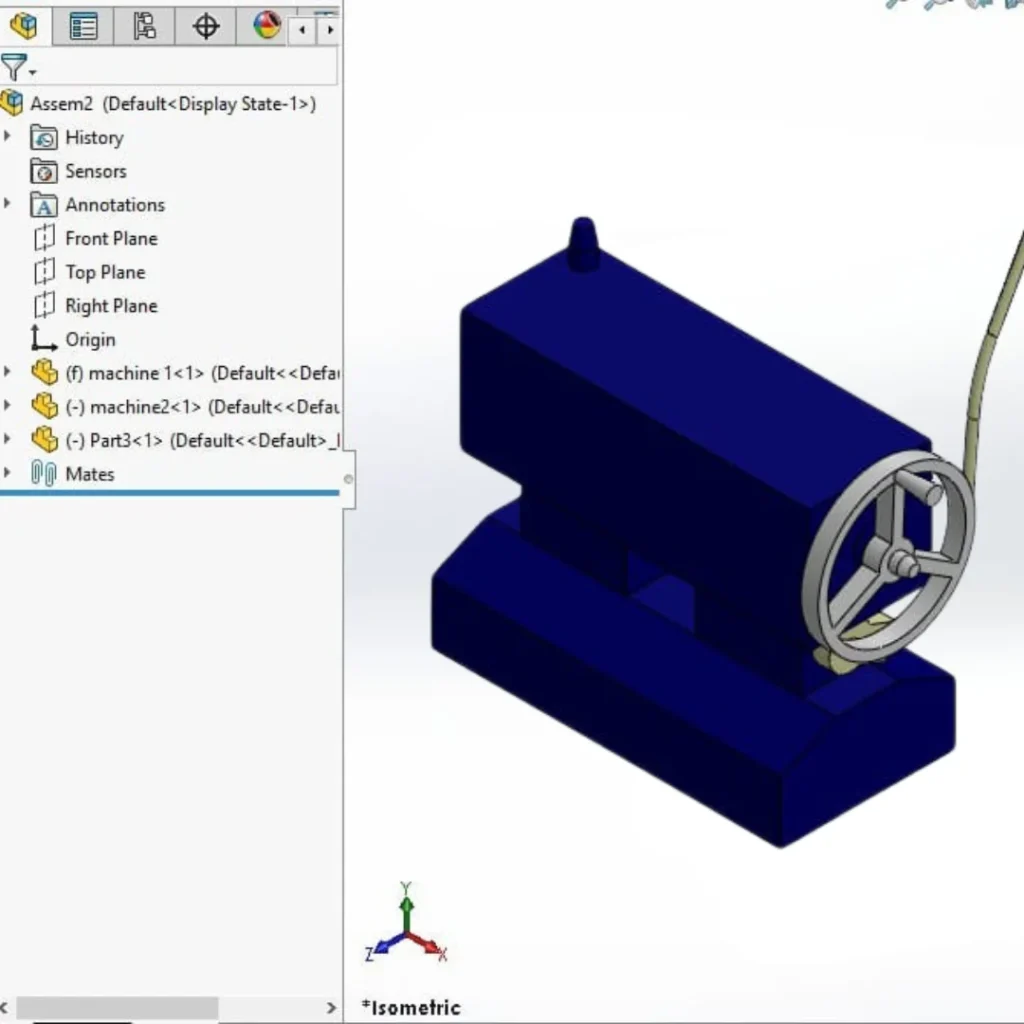

A client required a high-fidelity 3D CAD model of an industrial machine feed mechanism assembly for use in technical archives and presentations. This project focused on precision parametric modeling and rigorous assembly mating, ensuring the digital asset was geometrically accurate, visually clean, and fully flexible for future design modifications or detailed rendering.

How This Project Took Shape Step by Step

High-Fidelity Part Modeling

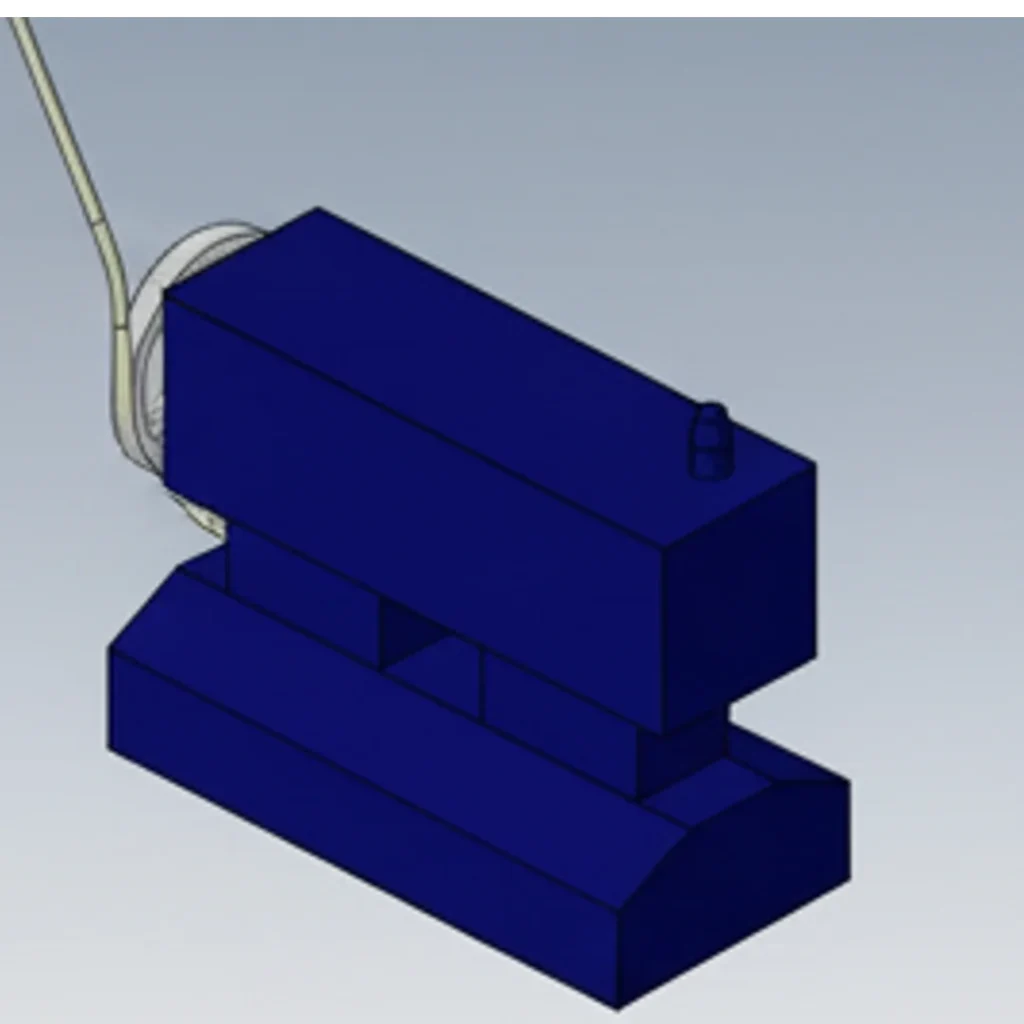

Created clean, detailed 3D CAD models for all five components of the industrial mechanism, using robust construction techniques to ensure geometric integrity. This provided a flawless digital foundation for the entire assembly, optimizing the geometry specifically for archival and rendering purposes, maximizing the visual fidelity of the final asset.

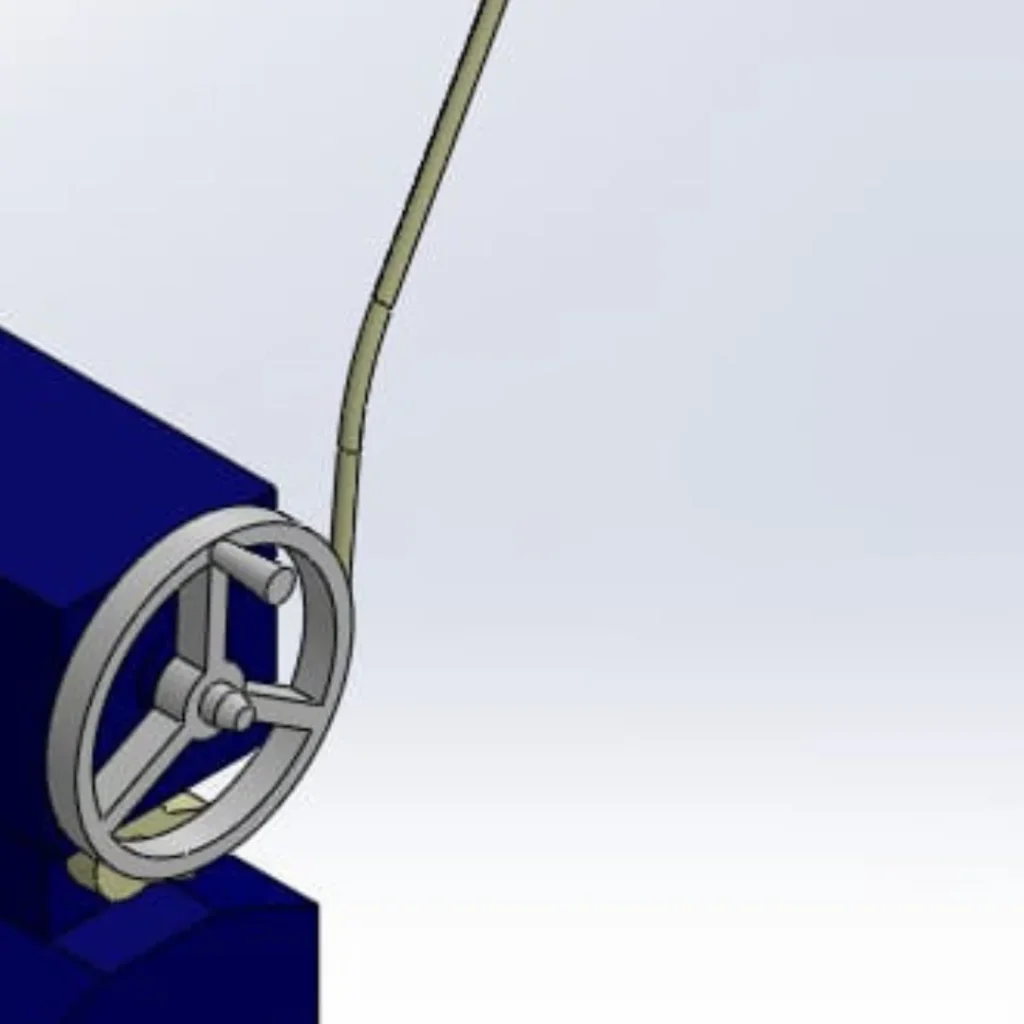

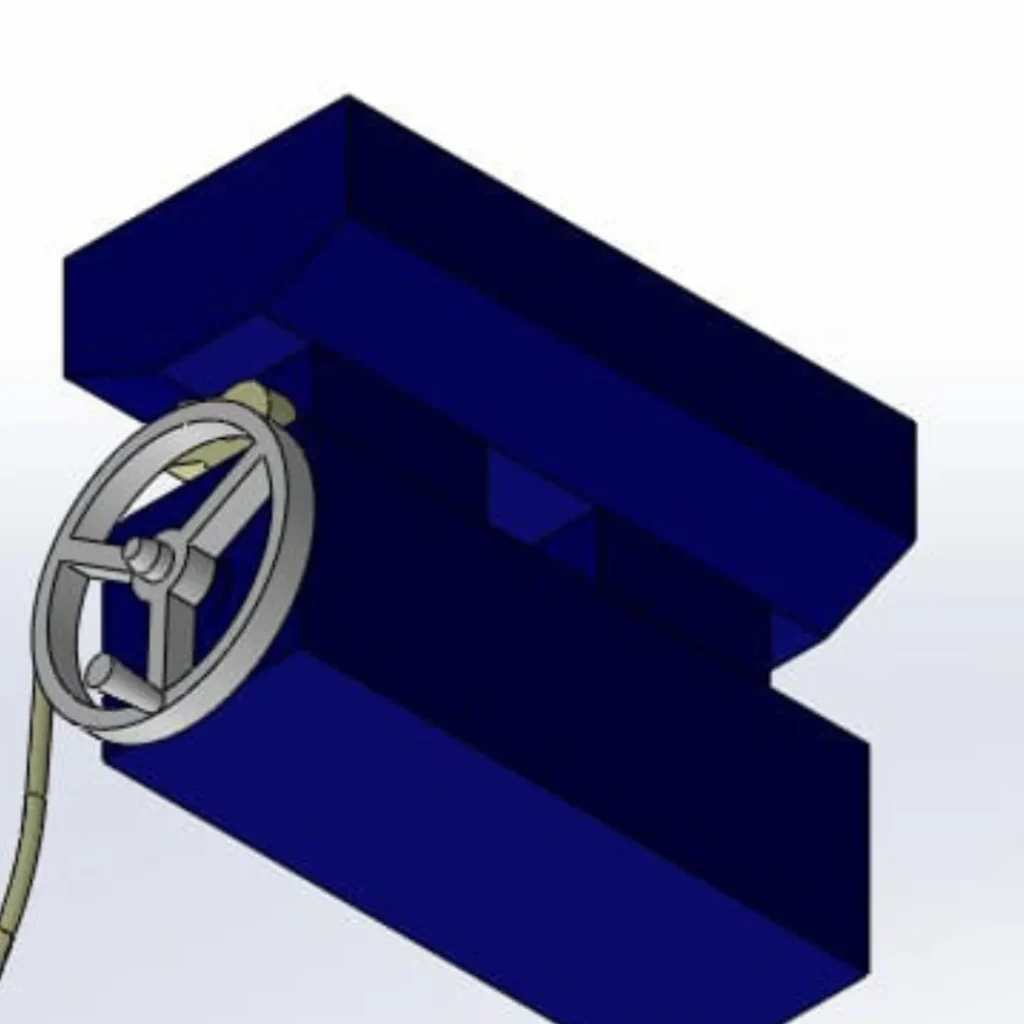

Multi-Part Assembly Mating

Defined all necessary rotational and axial mates in the SolidWorks assembly environment to precisely verify the mechanical relationship and smooth, intended movement of the components (wheel, handle, and housing). This rigor guarantees the digital mechanism functions correctly within the virtual space, which is essential for detailed internal presentations.

Dimensional Integrity Check

Performed rigorous verification of all critical interface dimensions and clearances, confirming that the digital model met all required geometric accuracy standards. This ensures the final rendered asset is dimensionally trustworthy for technical archives and high-resolution visualization, maintaining the integrity of the original design intent.

Clean Parametric History

Ensured the entire model history was meticulously cleaned, structured, and fully parametrically linked using robust feature management techniques. This delivers maximum flexibility for the client’s future internal revisions, making the model scalable and easy to modify without destructive errors.

Visualization & Rendering Prep

Applied realistic material textures and prepared the model geometry with optimized surfacing for high-fidelity rendering output. This process ensures the final visual asset meets the stringent quality standards required for technical documentation and professional presentation use.

Final CAD Archive Handover

Delivered the native SolidWorks CAD files along with neutral formats (STEP, IGES) optimized for long-term archival and viewing across multiple software platforms. This robust handover provides a secure, flexible, and reliable technical asset for the client’s library.

What the Client Shared About This Project

Every project is complete once the results match what the client envisioned. Here’s their perspective on the process, communication, and final outcome.

The objective was visualization and documentation purity. The final 3D CAD model was geometrically flawless, and the clean parametric history made it incredibly easy for our team to integrate into our technical archives. It was exactly the high-fidelity asset we needed for our internal presentations.

Hassan Al-Masri

Engineering Student

Have We Worked Together?

You can share your experience and help others understand what it’s like to collaborate with me on engineering projects.

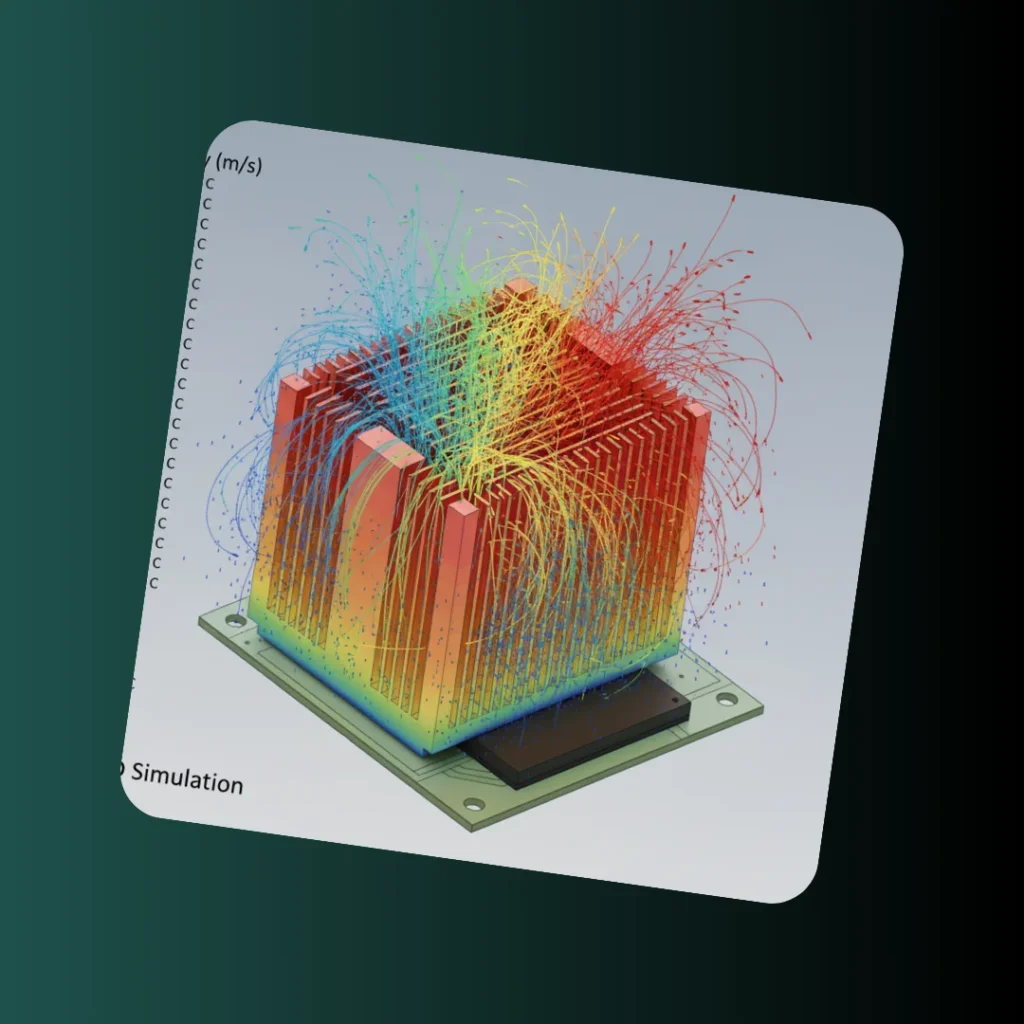

Thermal Management: Optimizing Heat Sink Design for Electronics Reliability

The objective was to design and validate an optimized heat sink to ensure a critical electronic component (e.g., CPU, power transistor) operates within safe thermal limits. This project utilized ANSYS …

Analysis SoftwareANSYS Steady ThermalThermal ComplianceVerified Max TemperatureCooling PerformanceHeat Dissipation OptimizedFin GeometryDesign Iterations Checked

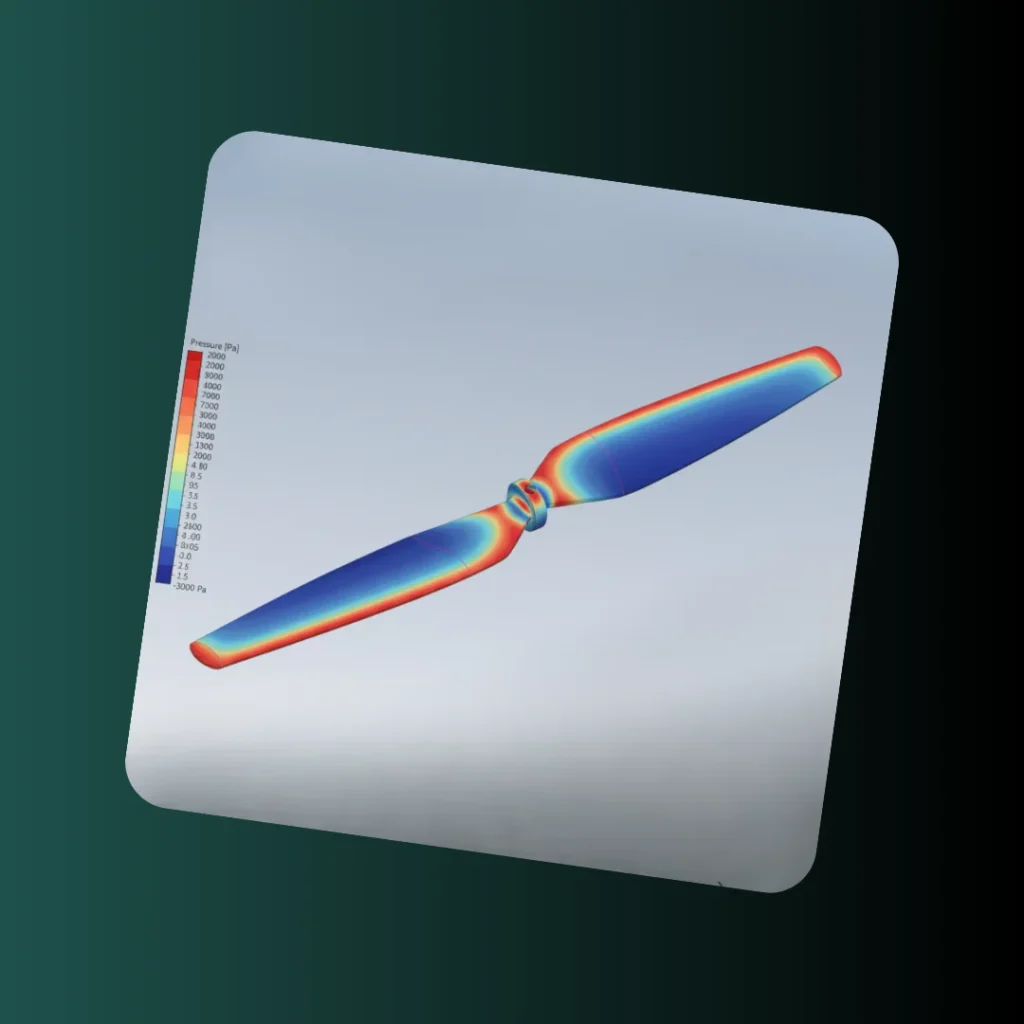

Aerodynamic Optimization: Enhancing Drone Propeller Thrust and Efficiency

The objective was to optimize a drone propeller blade design using advanced CFD analysis to maximize thrust and efficiency under various flight conditions. This project utilized ANSYS Fluent to model …

Efficiency GoalMaximize Thrust/TorqueAnalysis SoftwareANSYS Fluent CFDFlow ModelingComplex Airflow SolvedOptimization FocusAerodynamic Efficiency

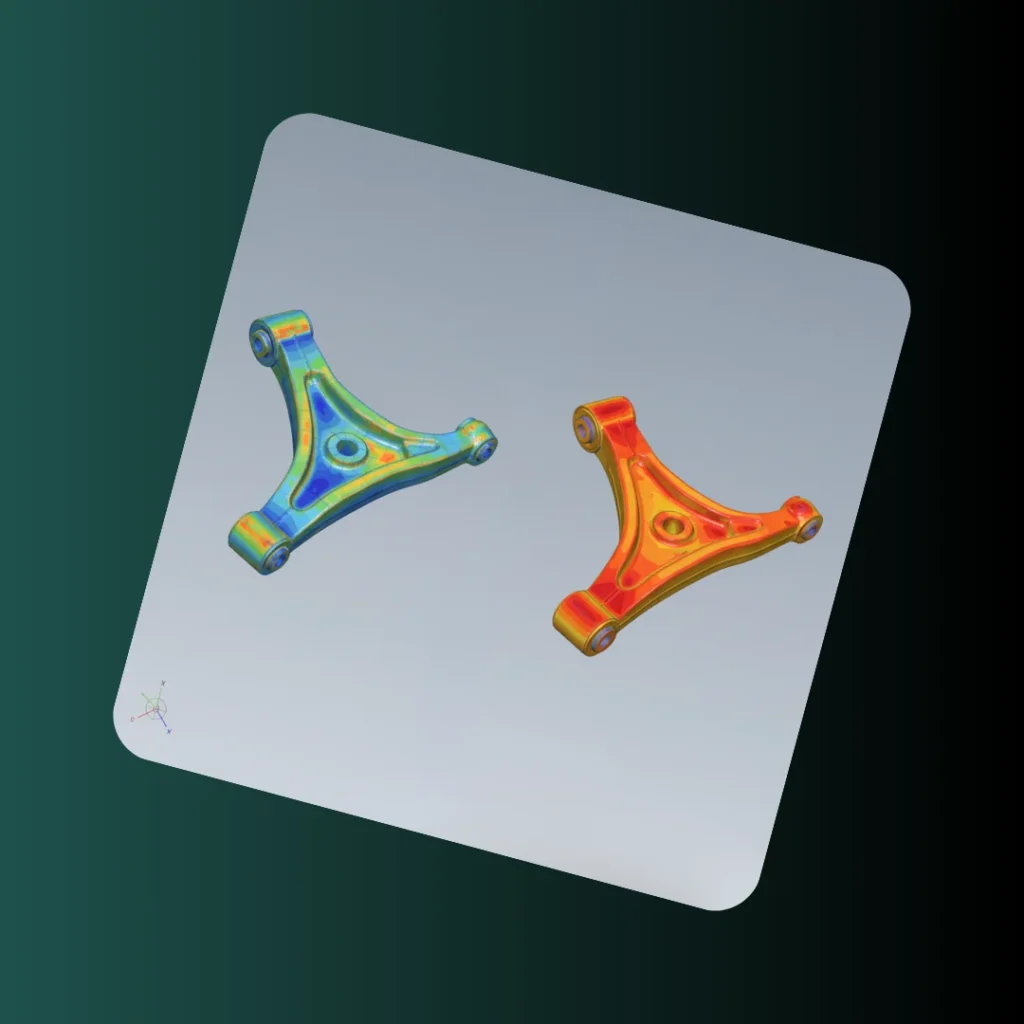

Structural Reliability Audit: Reverse Engineering of Suspension Component

The objective was to take a client’s legacy engineering drawing of an automotive suspension component and perform a detailed structural FEA verification under simulated operating loads. This project utilized 2D-to-3D …

Data OriginEngineering Drawing DataReliability MetricFactor of SafetyVerification MethodSimulated Load TestingDesign StatusVerified Safety Critical

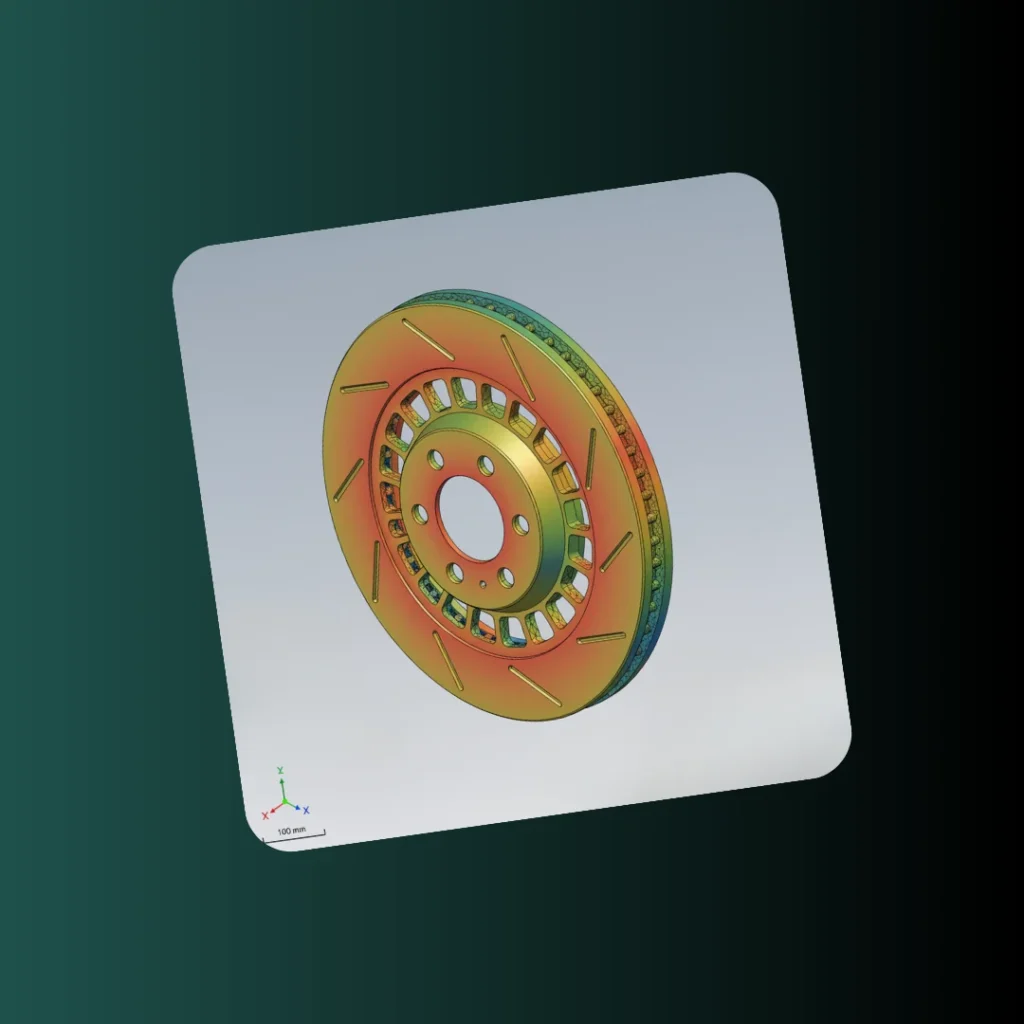

Static Structural Analysis: Verifying Automotive Brake Rotor Reliability

The client needed to model their theoretical brake rotor design and verify its performance under maximum load conditions. This project utilized SolidWorks CAD modeling and ANSYS Static Structural analysis to …

Analysis SoftwareANSYS Static StructuralCritical ResultStress/Strain CheckedReliability MetricFactor of SafetyDesign StatusVerified Reliable

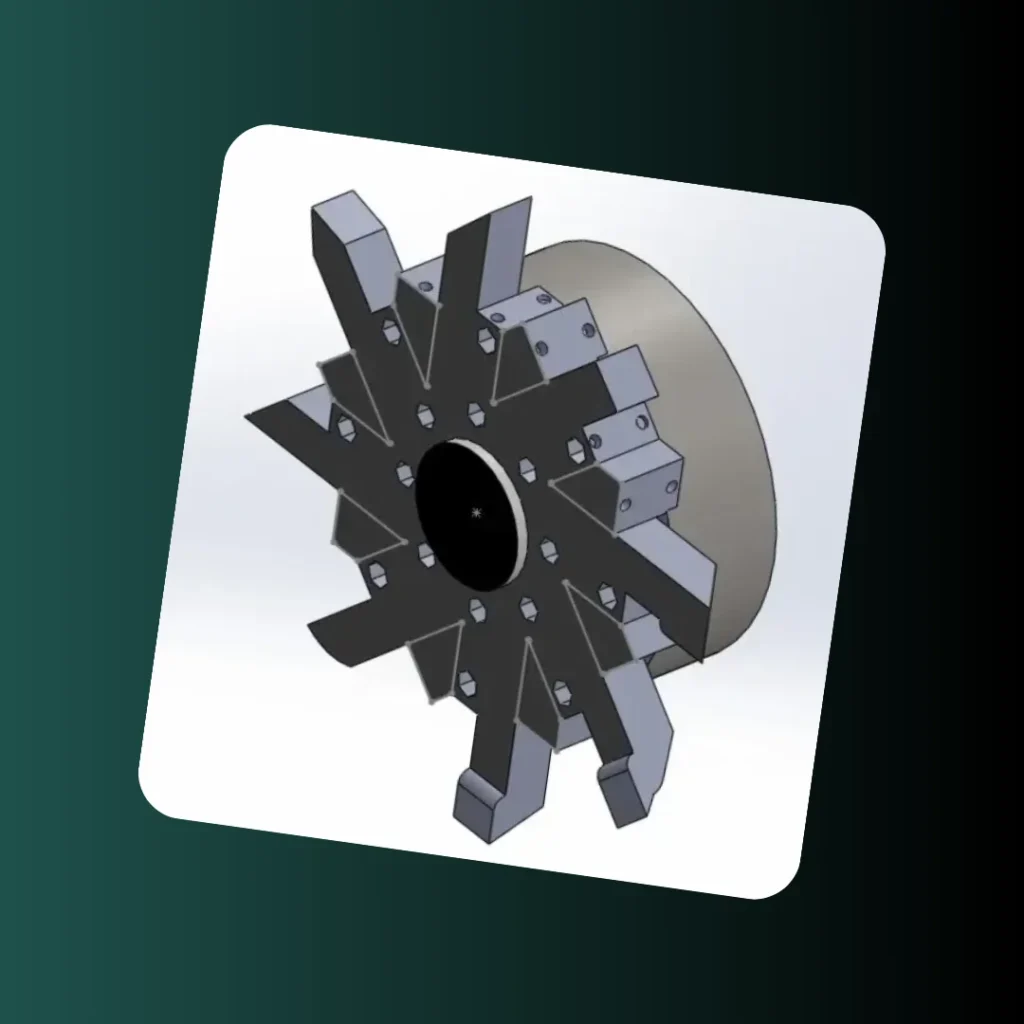

CNC Tool Turret: High-Precision Assembly and Indexing Verification

The requirement was to create a precise, high-fidelity 3D CAD model for a CNC machine tool turret assembly, ensuring the accurate rotational mating and precise indexing of multiple cutting tools. …

Primary ServicesCAD/DFM / Design ForensicsTool Capacity08 Tool StationsComponent RigidityHigh Structural IntegritySoftware UsedSolidWorks Assembly

Have a Project in Mind?

If you’re working on a product, simulation, CAD model, or need engineering support, I’d be happy to help you turn it into something precise and functional.