This is just a placeholder headline, we will replace it.

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet.

Predictive Engineering: Structural Reliability and Fatigue Life Validation

Stop designing based on assumptions. I provide specialized structural FEA consulting to predict mechanical reliability, fatigue life, and stress distribution before manufacturing begins. This service delivers verifiable data and deep technical insight, guaranteeing your systems perform reliably under real-world stress and dynamic conditions.

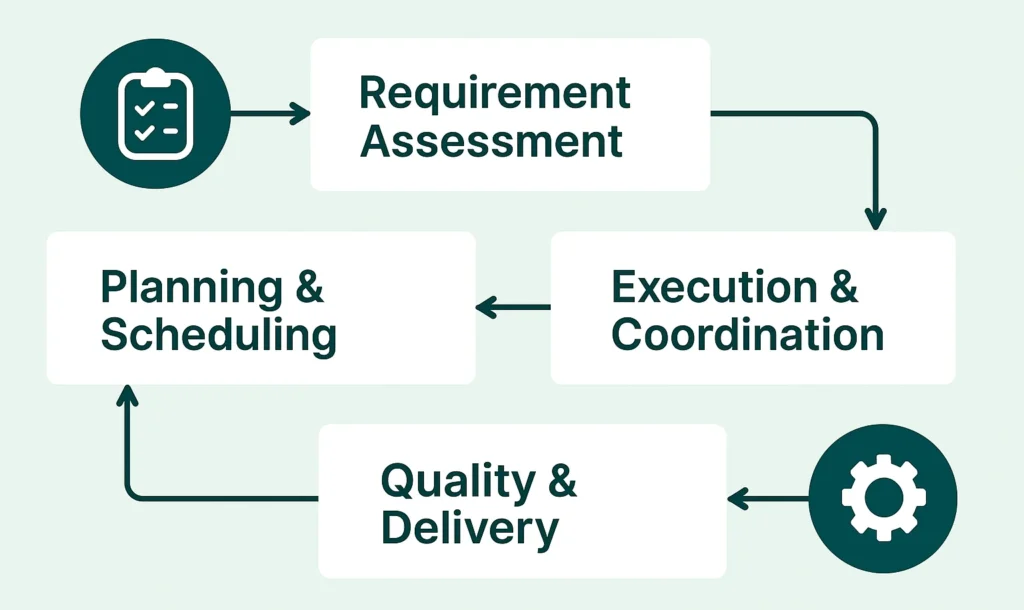

The 6-Phase Structural Validation Methodology

High-stakes structural projects demand an audited system, not reliance on generic software defaults. This comprehensive methodology ensures every analysis is set up, executed, and verified against engineering standards, translating raw data into guaranteed structural reliability and optimal performance.

CAD Geometry Preparation

Preparing the CAD geometry by simplifying topology and removing non-essential features, ensuring computational stability and maximum accuracy for the analysis.

Meshing & Element Optimization

Creating the optimal finite element mesh to balance solution speed against accuracy. This step is critical for correctly capturing stress gradients in sensitive geometric regions.

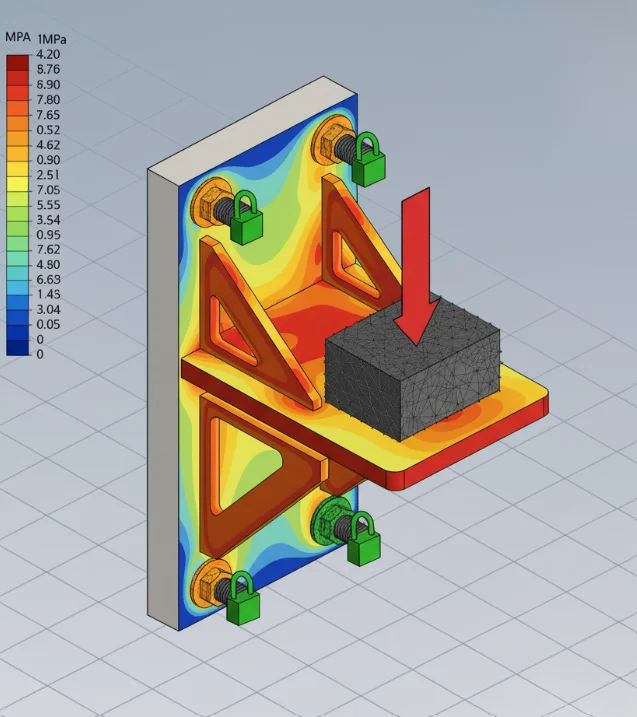

Boundary Conditions Setup

Precisely establishing loads, material models, constraints, and failure criteria based on real-world operational standards and anticipated static or dynamic analysis.

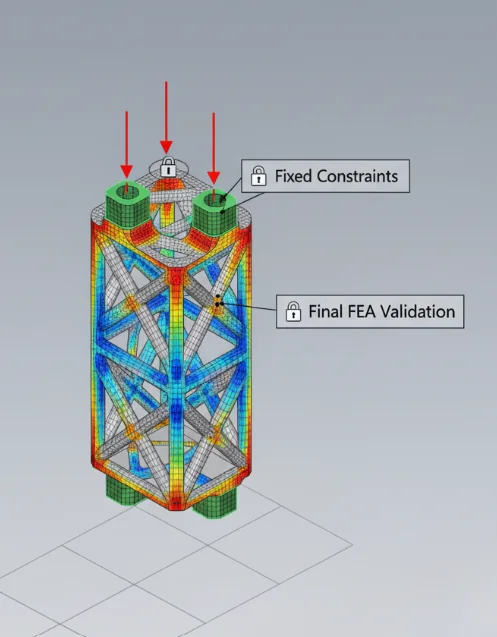

Non-Linearity & Solver Execution

Running advanced solvers to investigate complex mechanical behaviors, including non-linearity (material, contact, or large geometry) and buckling or ultimate failure loads (S_R1, S_R4).

Post-Processing & Insight

Extracting data visualization (stress plots, deformation, safety factors) and identifying critical fatigue zones (S_R1) or structural weaknesses for targeted improvement.

Recommendation & Design Loop

Converting complex simulation data into clear, actionable design improvements (size, shape, or material distribution) to achieve guaranteed structural reliability.

Data Certainty: The Measurable Advantages of Predictive Engineering

Designing without simulation is guesswork. This service provides the predictive intelligence required to maximize product lifespan, ensure compliance, and confidently guarantee performance. These benefits show how data-backed analysis becomes your competitive advantage.

Failure Risk Elimination

We predict component lifespan under cyclic loading, preventing the sudden, premature structural failure common in complex mechanical systems (S_R1, S_R7).

Dynamic Performance Validation

Specialized analysis of vibration, shock, and thermal expansion ensures that dynamic mechanisms (like your Isolator Assembly) perform reliably without destructive resonance or stress (S_R8).

Actionable, Clear Insight

We translate complex stress plots and data into clear, concise, and actionable design recommendations that your team can implement instantly, not just raw analytical output.

Optimize Weight and Structure

Utilize topology and optimization techniques to reduce unnecessary material mass (like in your Chassis design), achieving superior structural reliability without compromising load capacity (S_R8).

Direct Expert Partnership

You partner directly with a dedicated engineer who ensures the FEA analysis is perfectly aligned with your commercial goals, providing personalized support and accountability.

Reduced Development Costs

Virtually test every design iteration, eliminating the need for expensive physical prototypes and drastically accelerating your overall validation timeline.

Have a Design, Simulation, or CAM Requirement?

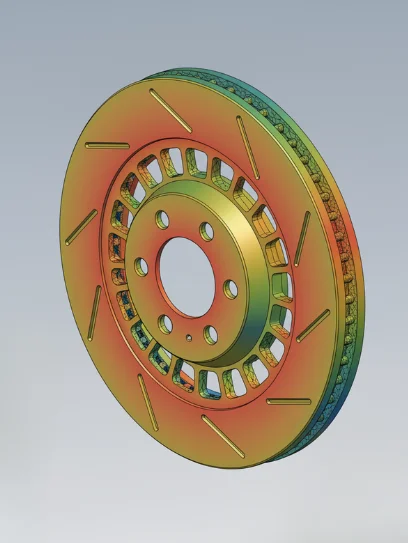

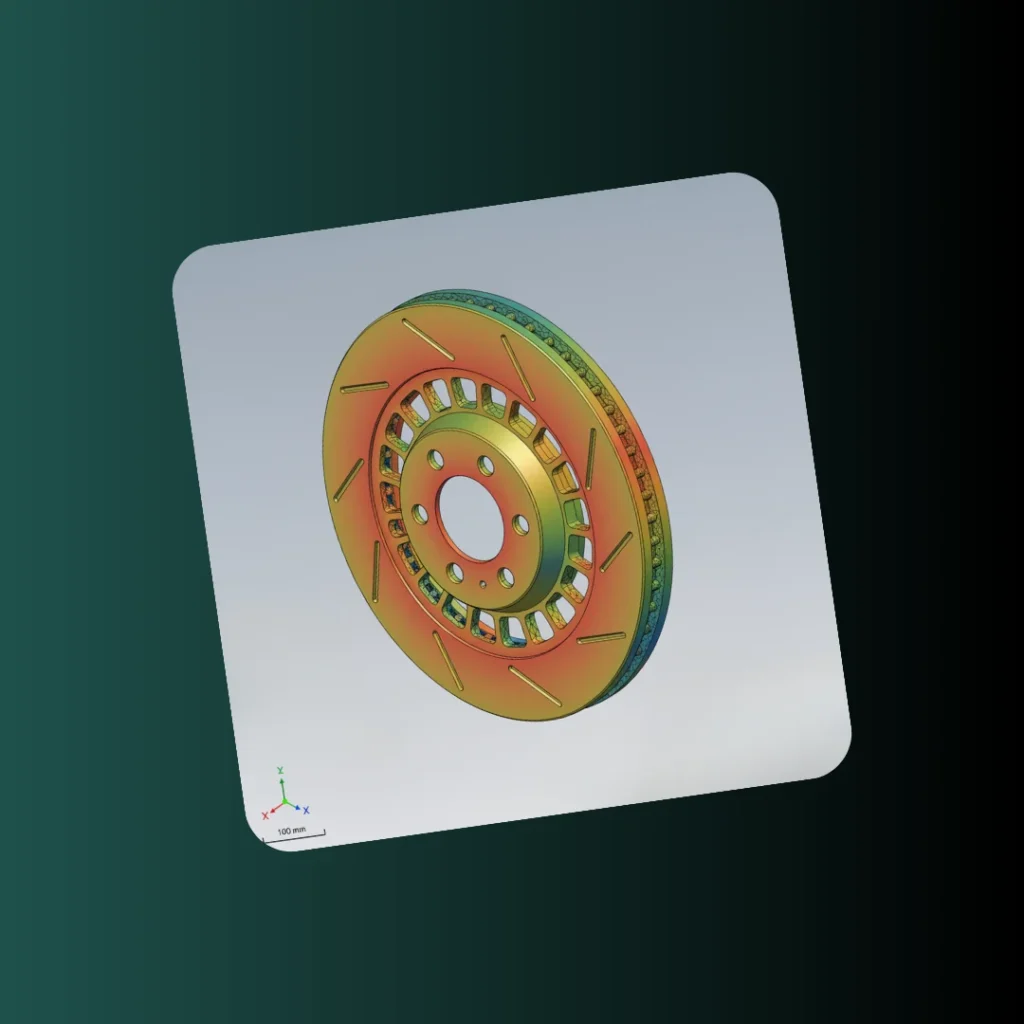

Static Structural Analysis: Verifying Automotive Brake Rotor Reliability

The client needed to model their theoretical brake rotor design and verify its performance under maximum load conditions. This project utilized SolidWorks CAD modeling and ANSYS Static Structural analysis to …

Analysis SoftwareANSYS Static StructuralCritical ResultStress/Strain CheckedReliability MetricFactor of SafetyDesign StatusVerified Reliable

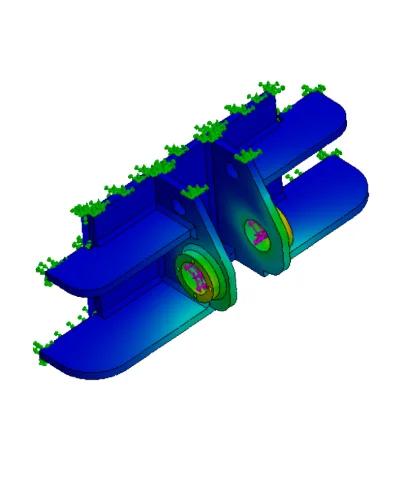

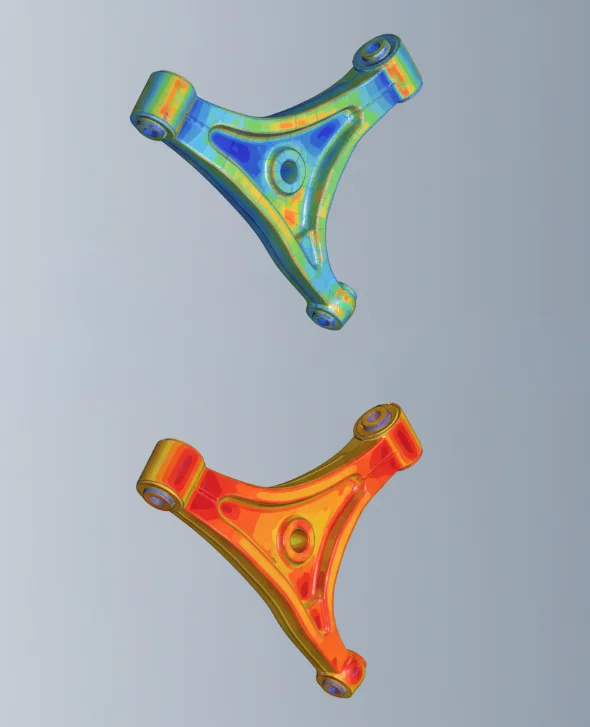

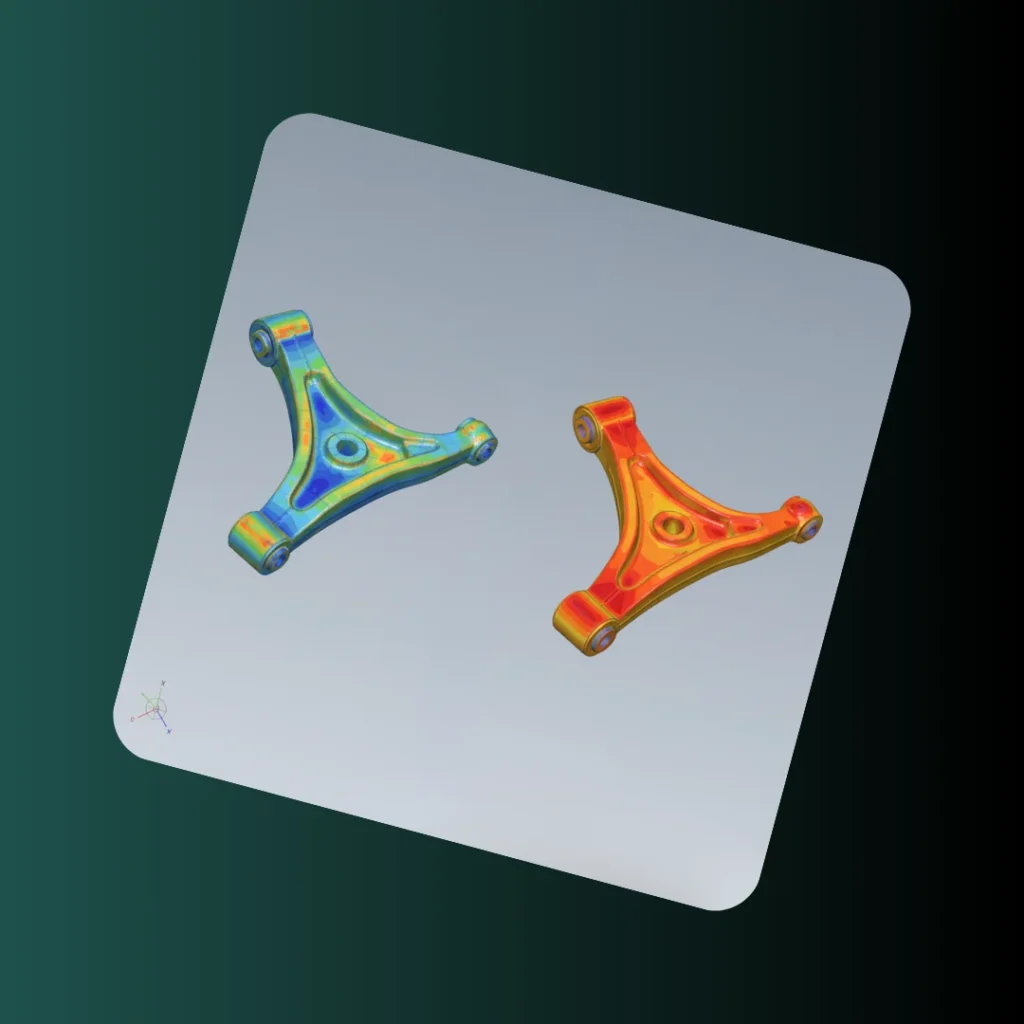

Structural Reliability Audit: Reverse Engineering of Suspension Component

The objective was to take a client’s legacy engineering drawing of an automotive suspension component and perform a detailed structural FEA verification under simulated operating loads. This project utilized 2D-to-3D …

Data OriginEngineering Drawing DataReliability MetricFactor of SafetyVerification MethodSimulated Load TestingDesign StatusVerified Safety Critical

Let’s Clear Things Up

What exactly is the main purpose of Structural FEA?

Structural FEA is the virtual stress and static analysis of mechanical components. Its purpose is to predict load capacity, deformation, and failure points before any costly physical prototype is built.

How can I reliably predict the fatigue life and lifespan of my components?

By running specialized high-cycle and low-cycle fatigue analyses (S_R5), we predict structural endurance under cyclic loading. This provides data certainty on when a part might fail, guaranteeing structural reliability (S_R9).

Which advanced software platforms do you use for high-level structural analysis?

I work with industry-leading platforms such as ANSYS and SolidWorks Simulation (S_R9, S_R10). This ensures your analysis is based on verified, robust, and industry-standard solver technology.

If my current prototype is failing, can FEA diagnose the root cause?

Yes. We use failure analysis (S_R5) to reverse engineer the problem. The simulation pinpoints the exact stress concentration or design weakness responsible for the structural failure.

How does investing in FEA save me money compared to traditional prototyping?

It eliminates the need to build and break multiple physical prototypes. We test dozens of virtual iterations instantly, drastically reducing development costs and accelerating your time-to-market.

Can these FEA reports be used to support technical compliance or certification?

Absolutely. The final validation report provides detailed stress plots and quantifiable data that are often required to support regulatory compliance and simplify product design validation (S_R5).

How reliable are the simulation results compared to real-world physical testing?

When the analysis is set up correctly (boundary conditions, meshing), simulation results are extremely reliable. I use a verified methodology to ensure the FEA model accurately reflects real-world structural behavior.

What kind of CAD file or design information do you require to start an analysis?

I require the clean, finished CAD geometry (preferably in a native format like SolidWorks or STEP) and clear documentation on the loads, constraints, and operational environment.

Do you handle dynamic problems, like vibration, shock, or thermal expansion?

Yes, I specialize in dynamic analysis and transient thermal simulation (S_R8). We ensure your assemblies are safe from excessive vibration, sudden impacts, and stress caused by temperature changes.

What about complex failures like non-linearity or buckling?

I specifically audit designs for complex behaviors, including buckling (S_R8) and non-linearity (S_R4). This deep analysis ensures your system is safe and stable even under extreme or unexpected operational conditions.