This is just a placeholder headline, we will replace it.

This is just placeholder text. Don’t be alarmed, this is just here to fill up space since your finalized copy isn’t ready yet.

Root Cause Analysis: Uncovering the Why Behind Design Failure

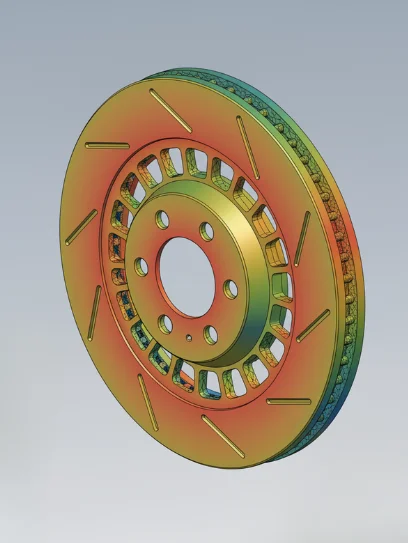

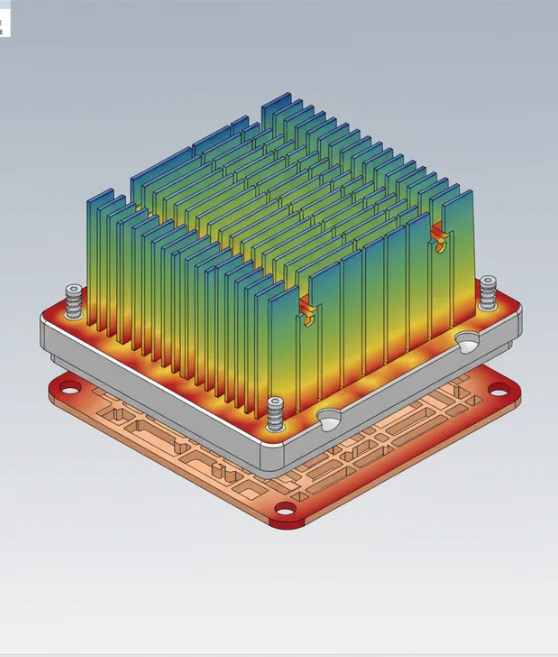

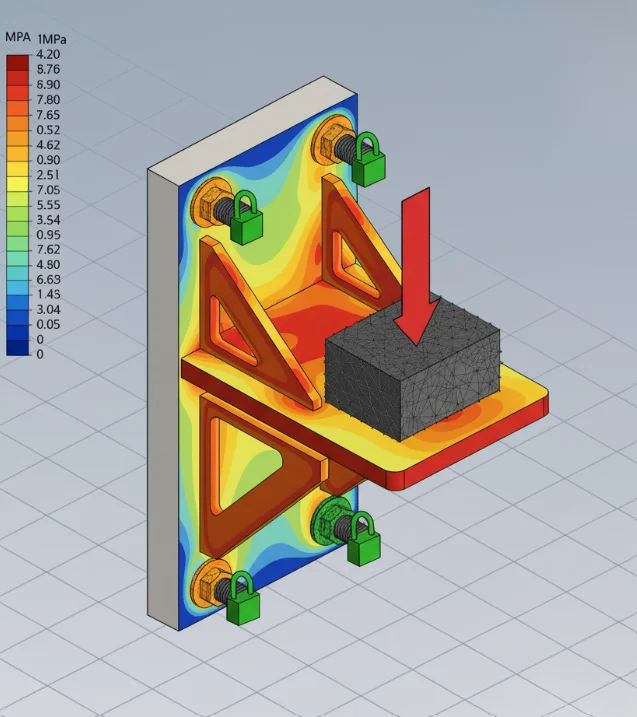

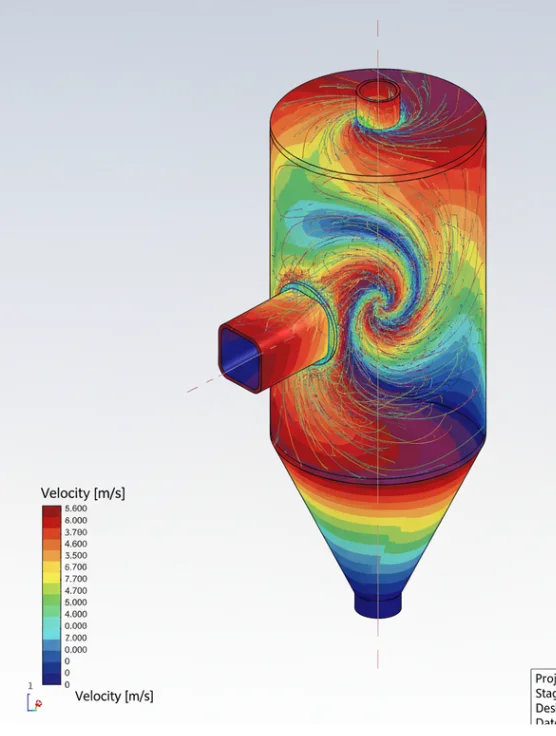

When an existing system underperforms or fails, you need an exact diagnosis, not guesswork. I utilize advanced simulation (FEA/CFD) and analytical reconstruction to systematically audit legacy or existing designs, identifying the root cause of failure, pinpointing inefficiencies, and providing actionable solutions for guaranteed optimal performance.

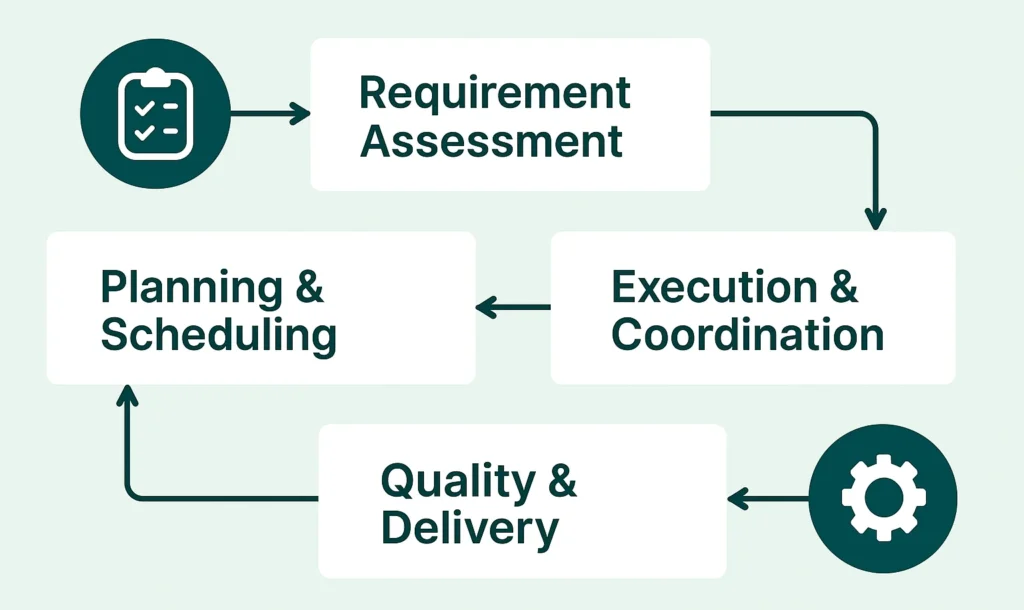

The 6-Phase Investigative Protocol for Design Reconstruction

Solving complex design failures demands a methodical, forensic approach. This protocol utilizes advanced simulation (FEA/CFD) and analytical reconstruction to find the true root cause of underperformance, ensuring the final output is a verified, optimized solution ready for immediate deployment.

System Audit & Data Collection

Begins with a forensic review of existing CAD geometry, assembly structure, legacy data, and observed failure modes to define the core problem (S_R2).

Analytical Reconstruction Setup

Building the virtual testing environment, establishing material models, loads, and boundary conditions to precisely replicate the real-world failure condition (S_R2).

Root Cause Failure Analysis

Utilizing FEA/CFD solvers to systematically isolate and identify the exact structural weakness, thermal stress, or flow anomaly responsible for the underperformance (S_R1, S_R15).

Post-Processing & Data Forensics

Translating complex simulation results (e.g., stress plots, flow vectors) into clear data points that confirm the failure mechanism and quantify inefficiency (S_R1).

Optimization & Re-Verification

Implementing precise geometric and structural changes (S_R15) in the CAD model, followed by simulation to guarantee the reconstructed design delivers guaranteed optimal performance.

Final Verified Solution Handover

Delivering the corrected CAD geometry, a formal root-cause audit report, and clear documentation showing the performance gains achieved (S_R2).

Data Certainty: The Measurable Advantages of Predictive Engineering

When failure is no longer an option, you need absolute certainty. This service provides the predictive intelligence required to diagnose complex design failures, guarantee reconstructed performance, and quickly recover costly projects through systematic analytical audit.

Pinpoint Root Cause Failure

We systematically identify the single structural, thermal, or flow anomaly responsible for the failure, eliminating guesswork and providing the definitive answer (S_R1, S_R15).

Modernize Legacy Systems

Expertly audit and optimize existing designs for modern performance and cost standards, extending the reliable lifespan of proprietary or older components (S_R7).

Immediate Cost Recovery

Stop funding repetitive physical testing or repair cycles. Analysis delivers the guaranteed fix virtually, turning design expense into investment recovery.

Guaranteed Performance Reconstruction

Receive a verified, corrected CAD geometry that is proven by simulation to perform reliably, eliminating the risk of repeated failure.

Clarity for All Stakeholders

We translate complex diagnostic data into clear, concise, and actionable audit reports for your technical, management, and procurement teams.

Singular Accountability

You partner directly with the expert conducting the analysis, ensuring consistency, deep project understanding, and zero miscommunication across the troubleshooting process.

Have a Design, Simulation, or CAM Requirement?

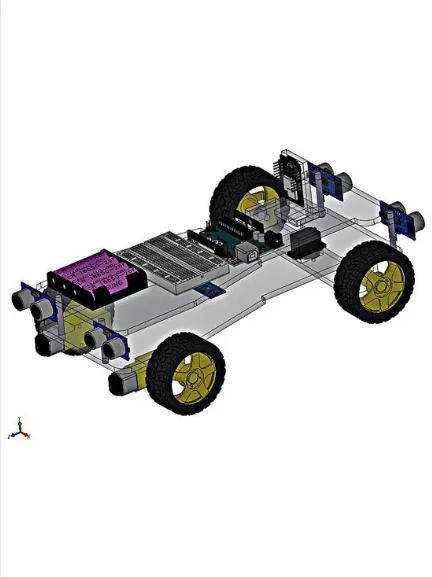

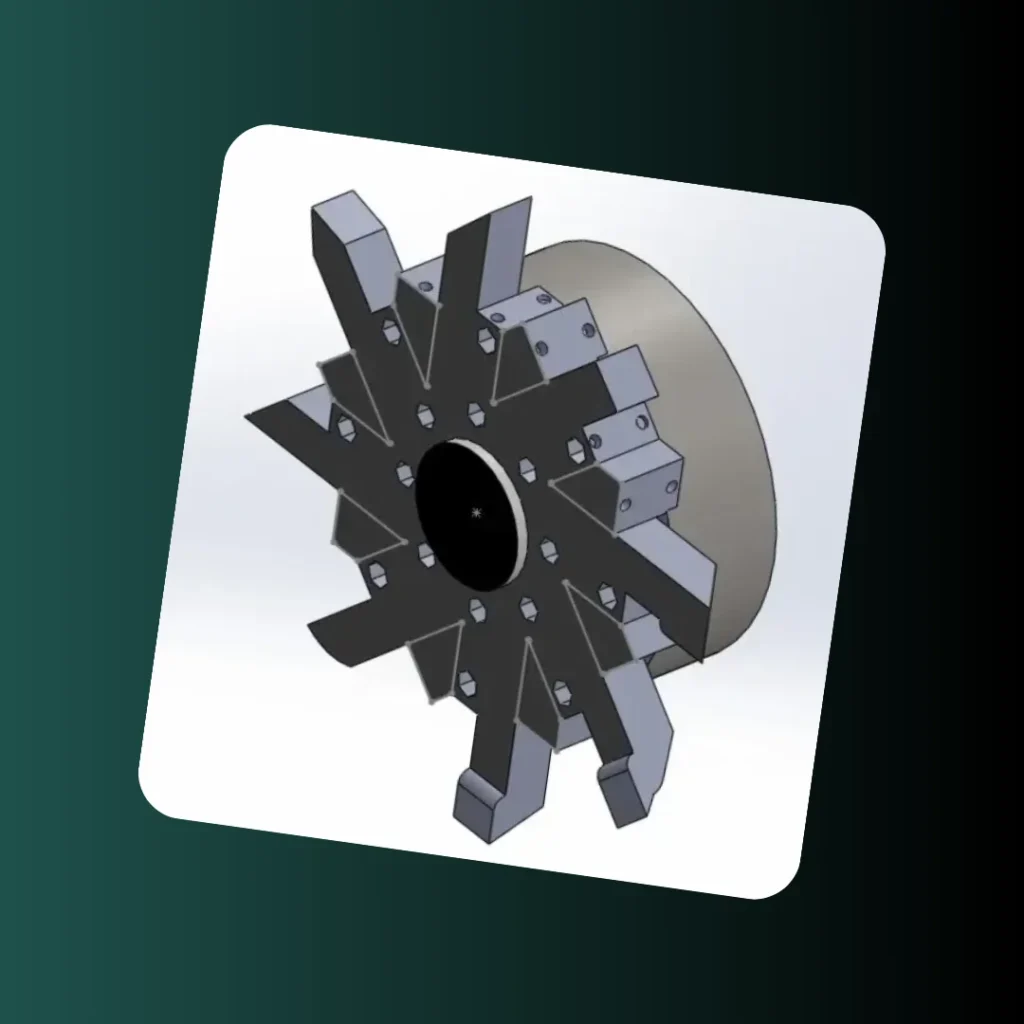

CNC Tool Turret: High-Precision Assembly and Indexing Verification

The requirement was to create a precise, high-fidelity 3D CAD model for a CNC machine tool turret assembly, ensuring the accurate rotational mating and precise indexing of multiple cutting tools. …

Primary ServicesCAD/DFM / Design ForensicsTool Capacity08 Tool StationsComponent RigidityHigh Structural IntegritySoftware UsedSolidWorks Assembly

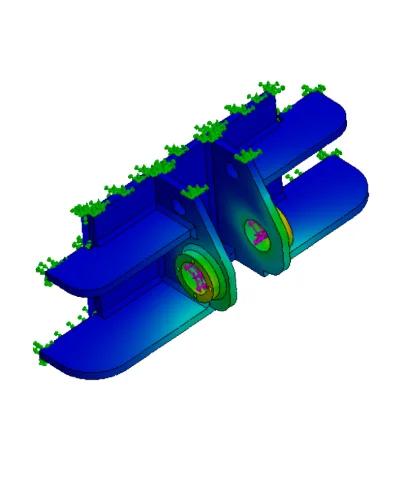

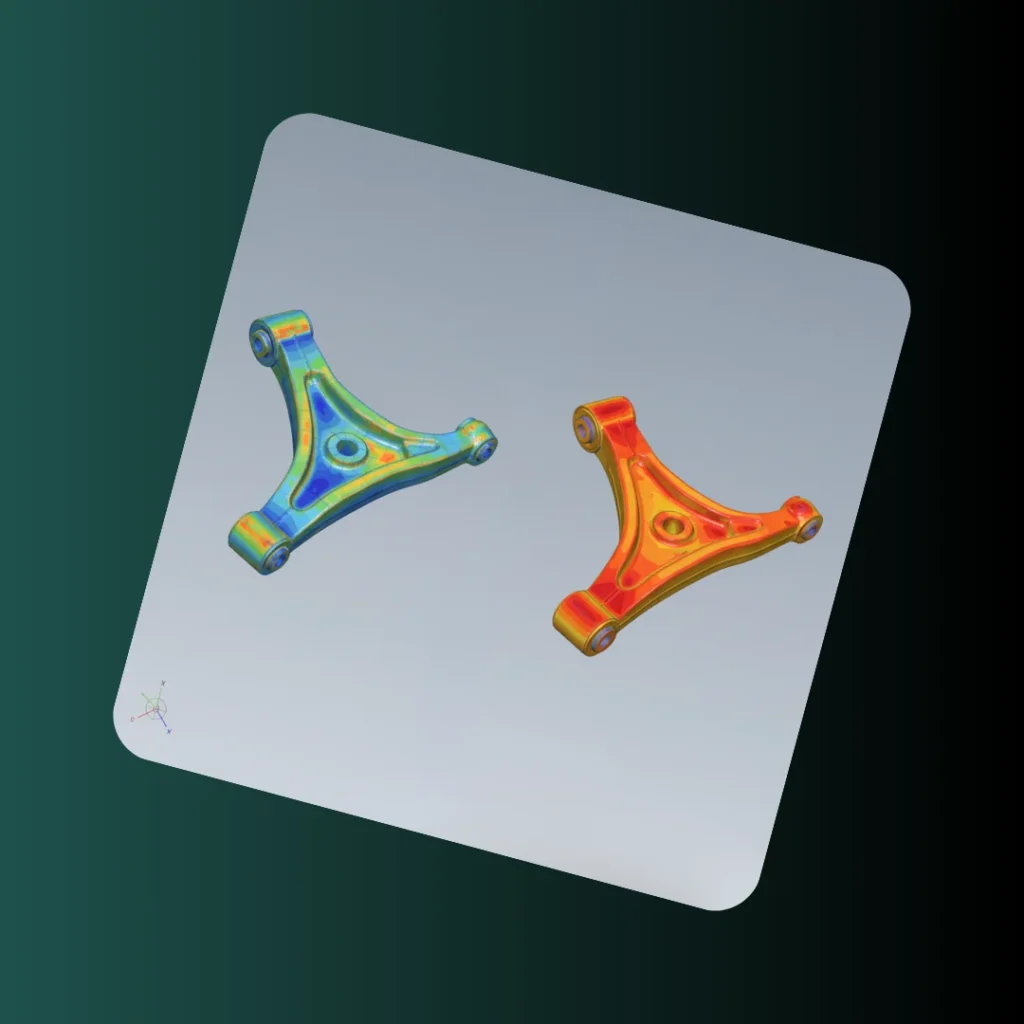

Structural Reliability Audit: Reverse Engineering of Suspension Component

The objective was to take a client’s legacy engineering drawing of an automotive suspension component and perform a detailed structural FEA verification under simulated operating loads. This project utilized 2D-to-3D …

Data OriginEngineering Drawing DataReliability MetricFactor of SafetyVerification MethodSimulated Load TestingDesign StatusVerified Safety Critical

Let’s Clear Things Up

What is the first step in diagnosing an existing design failure?

The process begins with a Forensic System Audit. We gather all existing data, perform analytical reconstruction, and define the failure mode to build a precise virtual testing environment (S_R2).

How do you find the root cause of structural failure or underperformance?

We use advanced FEA/CFD solvers to systematically simulate the exact conditions that led to failure (S_R1). This pinpoints the single critical stress concentration, material flaw, or flow anomaly responsible.

Can you optimize and update legacy CAD files that are structurally unsound or obsolete?

Yes. I specialize in Legacy System Optimization. I reconstruct the old geometry using modern parametric techniques and validate it with simulation to meet current performance standards (S_R7).

What if I only have old or messy CAD files for the failing system?

We start by performing CAD geometry preparation and reconstruction. The messy file is simplified, cleaned, and rebuilt into a stable, associative model suitable for accurate analysis (S_R2).

How do I know the reconstructed design won’t fail again after implementation?

The reconstructed design is verified using the same FEA/CFD solver under all critical load conditions before handover. The optimization loop guarantees the fix addresses the root cause (S_R2).

Is this forensic analysis more expensive than running a regular simulation?

While it involves deeper investigation, it is infinitely cheaper than repeating physical failures. Analytical Reconstruction quickly recovers development costs by providing a guaranteed fix the first time.

Do you handle complex simulation errors found during internal testing?

Yes, I specialize in troubleshooting simulation errors related to non-linearity, convergence issues, and complex dynamic states that challenge general solvers (S_R1, S_R2).

Do you offer support after the corrected file has been implemented in production?

Yes. I provide short-term support to the manufacturing team to ensure the new file integrates seamlessly, cementing our partnership and the success of the design reconstruction.